Condition: New

Range of Spindle Speed(r.p.m): 0 – 18000 rpm

Positioning Accuracy (mm): 0.01 mm

Number of Axes: 3

No. of Spindles: Single

Working Table Size(mm): 1300×2500

Machine Type: CNC Router

Travel (X Axis)(mm): 1300 mm

Travel (Y Axis)(mm): 2500 mm

Repeatability (X/Y/Z) (mm): 0.01 mm

Spindle Motor Power(kW): 3kw

CNC or Not: CNC

Voltage: AC380V/220V,50HZ

Dimension(L*W*H): 3000*2000*1600

Power (kW): 25

Weight (KG): 1000

Control System Brand: NC Studio

Warranty: 1 Year

Key Selling Points: Easy to Operate

Applicable Industries: Hotels, Garment Shops, Machinery Repair Shops, Manufacturing Plant, Farms, Home Use, Construction works , Food & Beverage Shops, Other, Advertising Company

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Warranty of core components: 1 Year

Core Components: Bearing, Motor, Pump, Gear, PLC, Other, Engine, Gearbox

motor: 450b drives the motor

Spindle: 3KW water-cooled spindle motor

Function: Drilling, Grooving, Engraving, Sizing

transfer method: Z shaft screw drive, XY shaft rack drive

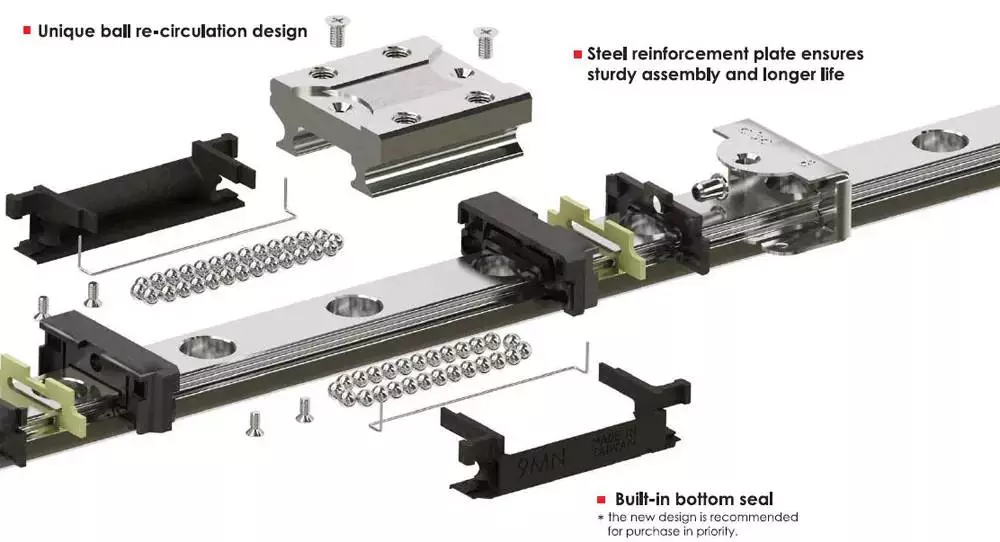

Xihu (West Lake) Dis. rail: ZheJiang high precision 20 square linear guide rail

function: Cutting, Hot selling massy ferguson tractor MF1204 the favorite brand with best model for you to choose in good mantainance carving, punching and milling

Grouped equipment: vacuum pump

Frequency converter: HangZhou Bested

warranty: One year warranty, lifetime maintenance

Packaging Details: standard wooden case or Stretch film

Port: HangZhou port

We are factory, not a distributor. We have our own workshop and accept equipment customization with favorable price. Our engraver can cut, carve, punch, slot, mill and so on. A multi-purpose machine, CNC control system, save labor. Support drawing import, custom processing. Features 1) Function :3kw water-cooled spindle, fast tool change speed, suitable for efficient cutting, slotting, milling and other processing of plate furniture;2) Structure: The heavy-duty body made of welded high-strength thick-wall steel pipe is stable in structure and guaranteed in precision after annealing aging and sandblasting.3) Accuracy: excellent accessories and precision testing devices, so that the product to obtain perfect positioning and operation accuracy;4) High speed: high-power stepper motor and precision screw connecting rod design, large torque, large kinetic energy, stable operation, high efficiency; OULUCCI 20mm Band For CZPT CZPT Watch SM-R810 42MM & Gear 2 Sport Strap For CZPT Amazfit BipAmazfit 2 Smart watch 5) Simple operation: compared with the traditional cutting method, only 1 person can operate, or even 1 person can operate multiple equipment, simple operation, high efficiency. Machine control interface design humanized, operators can start to work after simple training. Technical parameters Application 1.Board type furniture, custom-made furniture, ambry wardrobe, office furniture, tatami, computer desk, wooden sound box, wooden cabinet, cabinet door move door, blister door, indoor door, wooden door and other different processing.2.Advertising: Advertising signs, logo making, acrylic cutting, plastic molding, engraving on a variety of advertising decorative products materials.3.Other industry: relief, widely used in craft gifts industry, Wholesale simple long snake bone chain CZPT necklace 2571 design necklace for women Aluminum industry, Cutting aluminum, aluminum composite panel, aluminum honeycomb panels, aluminum profile, 3D ornamental engraving process, wave board production, LED, neon trough literal cutting, plastic mold making light box . Acrylic, copper, PVC board, artificial stone, MDF board and other types of sheet processing. Company Profile HangZhou Tuohan Intelligent Technology Co., Ltd. is a scientific and technological knowledge-intensive enterprise specializing in the production of woodworking machinery and glass processing machinery. It is a member of HangZhou Woodworking Machinery Association. After more than 10 years of development, we have strong technical force and perfect testing methods, as well as advanced technical advantages. Our factory has passed ISO9001 international system certification, and our main products have passed CE safety certification. Why Choose Us Own workshopWe have our own production workshop to ensure that all products use high-quality raw materials and accessories. The processed equipment will be shipped after being checked by the quality inspector. The equipment is of high quality and has a longer service life. One-stop serviceOur company has a number of production lines, which can provide a complete set of equipment for panel furniture processing production lines, and can also be customized according to customer requirements. Strong service teamAfter more than 10 years of development, our company has developed a number of patents. Through continuous technological improvement, our equipment has been at the leading domestic level. Our sales and after-sales personnel know the performance of the equipment well, OEM automotive Headlight lens cover mould Tail lens cover mold making automotive parts for LED TAIL LAMP cover part moulding ensuring customers have a good shopping experience. Packaging and Shipping

The Benefits of Using a Linear Rail in Your Industrial Machine

Generally speaking, linear rail is a material used for transportation. This material can be used in various different ways, including the transportation of goods and machinery. However, there are certain things that you should keep in mind before using it. These include the cost, the accuracy of travel, and the resistance to flexing.

Common uses

Using a linear rail can provide a variety of benefits. They provide low friction guidance, allow for a wide range of motion, and offer reliability. They are also compact and can be used for a variety of applications.

Linear rails are often used in automated assembly lines, conveyor systems, and machine tools. They also work well for pneumatic-driven systems. They can be used for moving loads from small to large in diameter and can handle speeds up to five meters per second. They are typically more expensive than other systems.

Linear rails come in a wide variety of designs. They can be mounted on a variety of surfaces and have different levels of load bearing capacity. They can also be used to connect multiple rails for very long travel lengths.

Linear rails are usually used in applications that require high accuracy. For example, they are often used in machine tools and laser welding machines. They are also used in the production of large objects. They are also used in 3D printing machines. They are also used in medical devices and special vehicles.

Linear rails require careful mounting. They need to be fully supported and have accurate mounting surfaces. They also need to be protected during assembly and shipping. Linear rails are typically made from steel or stainless steel. They are also available in a variety of sizes.

Linear slides are also known as linear motion bearings. They feature bearing contacts, plain surface bearings, recirculating or non-recirculating designs, and race profiles. The sliding contact guide rail is perfect for high accuracy applications.

Linear rails also have the capability to support overhung loads. They can be used alone or in combination with linear guides. They can withstand loads from a few grams to thousands of kilograms.

High level of travel accuracy

Using linear rails in your industrial machine will give you the benefits of a robust, well-supported design. They can handle loads of thousands of kilograms while reducing frictional drag. This is especially true for high-speed, heavy-duty applications.

The best part is that you can choose from a wide variety of options. From standard, multi-point, to end-to-end and even the modular type, there is a linear rail solution for your needs. Whether you want a low-cost solution or a high-end system, CZPT can help you with your industrial needs.

A high level of travel accuracy is a must for any linear stage. There are many factors to consider when choosing the best linear rails for your application. The best way to go about determining the best option is to determine your application’s specific needs and requirements. From there, the experts at CZPT can help you make a well-informed decision. They are experts in all things linear and can recommend the best options for your particular needs.

Aside from high travel accuracy, linear rails offer a multitude of other benefits. For instance, you can minimize the motion of the rails by mounting them in parallel. This will increase the life of the bearings while also reducing the deflection of the system as a whole. You can also choose a rail system that will accommodate overhung loads. This is especially true for linear applications that have high-speed, heavy-duty needs.

The high-tech industry has been abuzz with a number of new and exciting innovations. One such is the integration of an I-beam support with a linear guide system. The I-beam support is ideal for industrial applications, such as robotics.

Resistance to flexing

Besides being a spruced up version of the ancient horseshoe, the linear rail has some impressive properties, including its ability to bend without breaking, and a high degree of self-alignment. It also has the honor of being one of the only types of rails that will withstand a plethora of shocks and jolts, and has some of the lowest lifecycle costs in its class. A large number of rails are actually made from polymer rather than aluminum, but that is another story altogether. The most expensive rails are manufactured from aluminum. The best ones are made from a proprietary polymer, which is said to have the lowest lifecycle costs.

There are two main types of linear rails, the standard type which are fixed at one end, and the more modern and modern variant, which are self-aligned. The latter is actually more important than the former. A good rule of thumb is to consider the more expensive variants first, as they are suited to more rigorous testing and inspection.

Easy to machine

Choosing the right linear rail system depends on the specific needs of the enterprise. It is important to consider how long the rail will last, as well as other factors that can influence its lifespan.

Linear rail systems are designed to support the movement of equipment through production. The system is easy to maintain and is suitable for high-speed applications.

Linear rails are typically supported by aluminum extrusions. They are commonly fixed at each end of the rail. Linear rails can have short lengths or longer dimensions. They are commonly installed with hex slot screws along the length of the rail. Additional linear rail screws can be installed to increase the rigidity of the rail system.

Linear rails have higher load-bearing capacity than hard rails. Hard rails are used in heavy-duty applications, such as machining large molds. Linear rails are suitable for more precision applications, such as small precision molds.

Linear rails have higher accuracy. In addition, they provide a smooth motion. Linear rails also offer less resistance to bending and vibration. However, the use of linear rails requires more support during installation. In addition, the assembly process is tedious.

Linear rails can be used in a wide variety of industries. They are also useful in CNC machining. Most finishing machine tools are manufactured using high-precision linear rails.

Linear rails have higher requirements for processing and transportation. They can also be more expensive to maintain. However, they provide high-speed operation that improves precision. They are also easier to replace than hard track. The process is similar to replacing a screw.

Choosing a rail depends on the enterprise’s production. Some rails have high load-bearing capacity, while others are less expensive. The running speed of the rail system is also a factor.

Cost

Choosing the right rail can give significant advantages in both performance and durability. While there are many types of rails on the market, a good guideline can help you determine which one is best for your application.

The right rail can reduce your application’s total cost of ownership. However, you should be careful not to make the mistake of installing the wrong one. If you install the wrong rail, you can end up with corrosion, excessive misalignment, noise, and reduced life expectancy.

The cost of linear rails will vary depending on the length of the rail, the type of rail, and the material it is made of. However, the most cost-effective rail is one that is made of corrosion resistant steel alloys.

The cost of linear rails is also dependent on the size of the rail. Typically, larger runners are more effective for higher load capacity applications.

Linear rails can also be manufactured in short lengths. However, installing one of these rails is not easy. They have different tools and require a different assembly process.

The cost of linear rails is 2.5 to four times higher than that of rods. While the cost is high, the benefits can be significant. A linear rail provides high rigidity, high accuracy, and higher speed. They are also less likely to bend or deform under heavy load.

The cost of linear rails is often offset by the ability to achieve high speed and precision. However, the cost of installing these rails is not worth it. The same motor can achieve higher speeds using linear rods. However, installing linear rails is a much more difficult process.

The cost of linear rails also depends on the environment where they will be installed. If the rail is placed in a dirty or wet environment, it may lead to reduced precision, corrosion, and damage.

editor by Cx 2023-07-07