Product Description

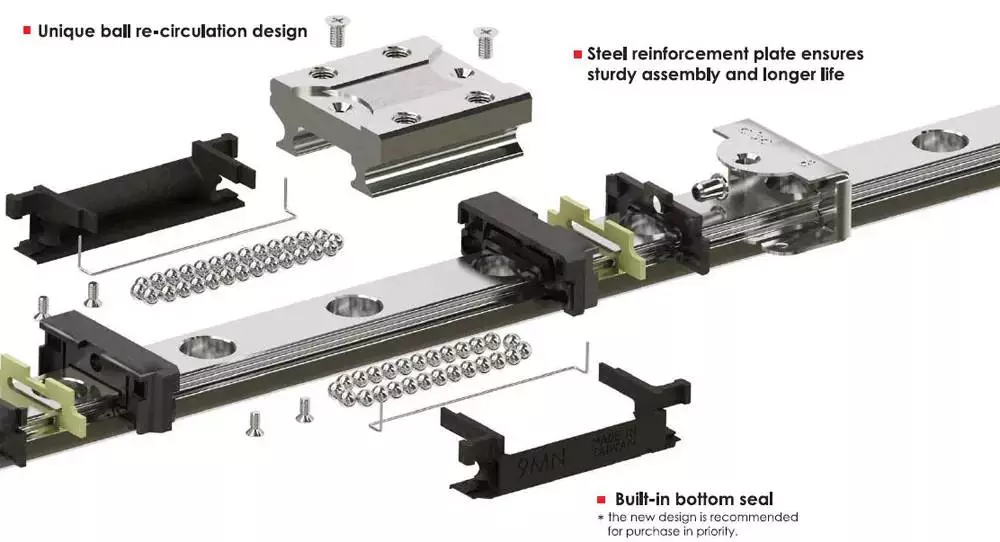

THK alternatives LM Block / Carriage / Rail / Linear Xihu (West Lake) Dis.

FSB Series

| Procuct Name | LM Linear Xihu (West Lake) Dis. FSB Series |

| Material | Chrome Steel/ Stainless Steel |

| Brand Name | HHLINE |

| Features | Good quality, Low price, CZPT alternatives |

Products Show:

Specifications:

Application:

About Us:

Established in China in 2016, Flow Tech represents around 30 leading suppliers and acts as their local sales agent. Also we get our own Chinese brands with high quality & low price. Products are divided into several business areas enabling the company to combined the advantage of being specialised in small areas with the benefits of being part of a large organisation. Further, with its ability to see the whole value chain and total costs, Flow Tech aims to improve its customers’ competitive advantage and profitability. The company’s ambition is to make life easier for its customers and to find the best and most cost-efficient solutions.

Why Choose Us?

Our Warehouse:

Packing and Delivery:

Packing:

Carton + Wooden Box + Pallet

FAQ:

Q: Is your linear guide can be CZPT alternatives ?

A: Sure, with a very competitive price and also the high quality level.

Q: How about the production time?

A: Generally 3-5 days if we get the stock.

Q: Do you provide samples?

A: Yes, but they are not free of charge.

Q: What is your payment terms?

A: 30% as deposit, and the balance before shipment.

Q: Can you arrange door to door delivery?

A: Sure, we can quote based on DDP, door to door, duty paid. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Feature: | Vacuum, Magnetically, Low Temperature, Corrosion Resistant, High Temperature, High Speed |

|---|---|

| Function: | Ordinary |

| Flange Shape: | Square |

| Shape: | Straight |

| Series: | LM |

| Material: | Bearing Steel |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing a Linear Rail

Whether you are using a linear rail for your business or home, you will find that there are some key considerations that you must keep in mind. These include the stability and accuracy of the system, as well as the cost of the rail.

Cost of linear rails

Choosing the right rail can be crucial to the performance and cost of a machine. There are many different types, with different levels of accuracy, load bearing capacity and rigidity. Some of the more common choices are drilled, profiled and undrilled.

The cost of linear rails can vary drastically depending on the type. Some are made from hardened steel, while others are fabricated from aluminum extrusions. Both types offer different advantages and disadvantages.

Rails that have been manufactured with aluminum extrusions will offer better rigidity. These rails also provide a larger range of motion.

Linear rails are generally used in mechanical systems that need high precision. These components must be fully supported and protected while being assembled. The assembly process is complex and time consuming.

These components are used in a wide variety of industrial applications. They can be used for transporting loads between two points or for guiding a moving part in linear motion.

Linear rails are usually manufactured from hardened steel, which is corrosion-resistant. Stainless steel is also commonly used. High-strength steel is also used. It is also known as cold drawn steel.

Rails have a high load bearing capacity and can handle loads from a few grams to a few tons. They offer smooth motion and can also be used to support overhung loads. Linear rails are generally used in automation machinery. They are also used in laser welding machines and bending machines.

Stiffness

Using a linear rail is a common solution for many industrial applications. These linear guides are known for their rigidity and load-bearing capabilities. They are designed to accommodate a wide variety of uses, including precision motion, high load capacities, and high speed operation.

These linear guides are available in various sizes and shapes, including cylindrical rollers, spherical balls, and race profiles. Each type offers different load capacities, speeds, and accuracy levels. They are typically used in applications that require precision, such as machine tools.

They are typically fixed at the ends. They are designed to transfer weights along a predetermined vertical or horizontal course. Linear rails are usually made of toughened steel. They require hex slot screws along the length of the rail. They are also used to guide actuators driven by screws or belts.

These linear guides are designed to offer high travel accuracy, which is important for many machine tools. They also offer high rigidity, which is needed to support heavy loads.

The stiffness of a linear rail is generally higher than that of a round rail. They can handle travel speeds up to 5 meters per second. They can support thousands of kilograms. They are also less likely to bend under heavy load, which can prevent misalignment problems.

Linear guides are often used in pneumatic-driven systems. They also have a rolling-friction operation mode. This reduces friction, which helps the machine tool to run smoothly.

Accuracy

Choosing the best linear rail depends on the application and the level of accuracy required. Some applications require high accuracy, while others are less demanding. A guide rail that has the right amount of preloading can minimize the effect of misalignment and sinking.

Rails are designed to withstand a variety of loads from a few grams to several tons. They can also handle moment and lift-off loads. Linear rails are made from high-strength steel that is galvanized.

A variety of processing methods are used to manufacture rails. Rails are available in square and round shapes. They can also be shaped to fit into smaller spaces.

The most accurate linear rail is the one that meets all of the above requirements. It can be difficult to know which rail is best for your application. It is important to consider the application and the total load conditions during the lifetime of the system.

It is also important to choose the most appropriate accuracy class for your application. Choosing the accuracy class of a rail is partially dependent on the positioning of the load and the mounting arrangement of the bearings.

For instance, the best accuracy class for a rail would be one that has a high preloading rate. This will increase the rigidity and minimize the effect of sinking. It will also increase the life of the component.

A linear rail that has a high preloading rate also has a higher accuracy class. This is because it will compensate for a lack of accuracy in the mounting surface.

Stability

Whether you’re moving items through a production process or handling heavy loads, you’ll appreciate the reliability and precision of a linear rail. It’s also important to consider the stability of your linear rail.

It’s important to design your linear rail with a complete support structure to prevent deflection. This may include mounting it on an I-beam support. This supports heavy loads and eliminates deflection concerns.

Linear rails also offer a wide range of motion, including the ability to support overhung loads. They are also suitable for guiding weights, providing a smooth motion in a single axis.

A single linear rail can also be used to guide actuators driven by screws or belts. These are commonly used in industrial applications. However, they may not be ideal for consumer applications.

For a more robust solution, you may consider using a dual rail. Dual linear rails maximize bearing life, and minimize deflection. These can also be anchored to aluminum extrusion profiles to improve stiffness.

Various types of materials can have a dramatic impact on the cost and performance of a project. These include stainless steel, which is corrosion-resistant and cold drawn. Other options include aluminum extrusion profiles and cylinders, which can reduce mechanical stresses.

In addition, the level of stiffness of your rail may be critical to its operation. In some applications, a rail may have to flex slightly in one plane. Using a cylinder instead of a sphere can also reduce play.

Sliding carriage and rail

Known for their rigidity and load-bearing capabilities, linear slides are ideal for applications that require repeatable motion. However, these units have a variety of components that can complicate their integration into your machine. Fortunately, there are a variety of products available that can help you find the right slide.

The main components of a linear slide include the carriage, bearings, guide rails, and control systems. The bearing system determines the accuracy of the slide.

Bearings can be a variety of shapes, including cylindrical and ball. They can be plain or filled with PTFE, ceramic, or metal. A ball screw drive with a motor may be necessary for stiff, reproducible slides. In less expensive applications, a round shaft system may be the best option.

Typically, the carriage is attached to the rail. The rail supports the carriage while it moves, and it can be a round rail, profiled rail, or linear stage. The carriage can be made of stainless steel, aluminum, granite, or other materials. Its threaded holes can be used for mounting tooling.

Carriage designs can be based on plain bearings, ball bearings, or cross rollers. Aside from simple surface bearings, these designs require lubrication. In less expensive applications, plain bearings may be sufficient.

Roller bearings are cylindrical roller load-bearing elements. They are used in track rollers and cam rollers. The rollers are inside the carriage and rotate with the carriage.

Applications

Whether you’re building an industrial automation system or simply need to move a load, the right linear guide can be a valuable tool. The benefits include high load capacity, reduced friction, high rigidity and increased accuracy.

The applications of linear rails can range from simple machine-tool applications to advanced medical applications. The most common applications include transportation and industrial machinery. However, the applications can also be found in the consumer space. Consumer health monitoring devices are a great example of applications that take advantage of linear motion.

Linear rails are a linear assembly consisting of load-supporting balls on each side and a pair of parallel tracks. Depending on the size and type of application, the load capacity can range from a few grams to several tons.

Linear rails are typically made from high-strength steel, which is profiled or galvanised. The rail is then cut to a specified length. Depending on the size, the cost of a linear guide rail will vary.

The linear rail’s name is a mouthful, but there are several models to choose from. Profiled rail guides are most suitable for high load applications.

The CZPT is a great choice for heavy-duty applications. It’s easily weldable, and can be ground smooth for easy transitions. The rail can be extended to long travel lengths.

The linear rail’s most notable attribute is its ability to withstand overhung loads. The rail can also handle moment and horizontal loads.

editor by Dream 2024-04-25

China supplier CNC Automatic Equipment 100mm-4000mm Roller Bearing Linear Guide Rail wholesaler

Product Description

Product Description

Product Description

TOCO Linear Motion Xihu (West Lake) Dis.way: HTH30

Application:

1. Automatic controlling machine

2. Semi-conductor industry

3. General industry machinery

4. Medical equipment

5. Solar energy equipment

6. Machine tool

7. Parking system

8. Woodworking machinery

9. Handling equipment

10. Grinder machinery

11. Tool machinery

12. High-speed rail and aviation transportation equipment, etc.

| Brand | TOCO |

| Model | HGH, HGW, EGH |

| Size customize | 15,20,25,30,35,45,55,65 |

| Style | With Flange or not ,butt Joint Process. |

| HS-CODE | 8487900000 |

| Items packing | Plastic bag+Cartons Or Wooden Packing |

| Payment terms | T/T, Western Union |

| Production lead time | 5~7 days for sample, 15~30 days for the bulk |

| Samples | Sample price range from $50 to $200. sample express request pay by clients |

| Application | CNC machines, Printing Machine, Paper-processing machine Machine tool, Solar energy equipment, Medical equipment, General industry machinery. Parking system |

Features

1. Low frictional resistance.

The linear guideway is a design of rolling motion with a low friction coefficient, and the difference between dynamic and static friction is very small. The frictional resistance of a linear guideway is only 1/20th to 1/40th of that in a slide guide. Therefore, the stick-slip will not occur when submicron feeding is making.

2. High precision maintained for a long period

The linear guideway with good lubrication can be easily achieved by supplying grease through the grease nipple on the carriage or utilizing a centralized oil pumping system, thus the frictional resistance is decreased and the accuracy could be maintained for long period.

3. Suitable for high-speed operation

Due to the characteristic of low frictional resistance, the required driving force is much lower than in other systems, thus the power consumption is small. Moreover, the temperature rising effect is small even under high-speed operation.

4. Easy installation with interchangeability

Compared with the high-skill required scrapping process of conventional slide guide, the linear guideway can offer high precision even if the mounting surface is machined by milling or grinding. Moreover, the interchangeability of linear guideway gives convenience for installation and future maintenance.

Model detial:

Company information

TOCO Group is a professional manufacturer in linear motion components in China, mastering critical core technology, focusing on research and innovative design.It has a number of product design patents and with ISO9001 certification, who is named a national high-tech enterprise.At present, there are 2 major production factories with a total area of 13,000 square meters.Thanks to a strong technical and production team, CZPT can quickly provide high-performance and high-quality transmission components for global customers, which has been widely recognized by domestic and foreign customers.

TOCO MOTION brand product line is complete, the main products are: Mono stage, linear module, linear guide, Ball screw, Support unit, Rack and Pinion.The products are widely used in: 1. Automation equipment 2. Display and semiconductor equipment 3. Woodworking equipment 4. Medical equipment 5. Photovoltaic and new energy equipment 6. Laser equipment 7. Machine tool equipment 8. Equipment in the fields of aerospace and rail transit, etc.

TOCO products are exported to more than a dozen countries and regions overseas.

FAQ

1. Service :

a. Help customer to choose correct model

b. Professional sales team, make your purchase smooth.

2.payment :

Sample order: We require 100% T/T in advance. sample express need request pay by clients

Bulk order: 30% T/T in advance, balance by T/T against copy of B/L.

T/T,Paypal, Western Union is acceptable.

3.Package & Shipping :

a.Package: Carton or wooden case.

b.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea

4.Delievery :

sample: 5-10 business days after payment confirmed.

Bulk order :10-20 workdays after deposit received .

5. Guarantee time

TOCO provides 1 year quality guarantee for the products from your purchase date, except the artificial damage.

6.After sale-service

During warranty period, any quality problem of CZPT product, once confirmed, we will send a new 1 to replace.

| Material: | Steel |

|---|---|

| Structure: | Other |

| Installation: | Other |

| Driven Type: | Other |

| Carrying Capacity: | Weight Level |

| Running Mode: | Moving |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to Get the Longest Life Out of Your Linear Rails

Whether you’re looking for the strength of steel or the convenience of aluminum, linear rails can provide you with the right choice. They can withstand both downward and lift-off loads, and they can be anchored along their full length to aluminum extrusion profiles.

Maintenance of linear rails

Depending on the environment you are using your linear rails in, it will vary as to the amount of maintenance that is required. However, there are some key steps you can take to make sure you get the longest life out of your rails.

The first step is to ensure you are installing your rails on a solid, level foundation. If your rails are not level, you may get indentations on your rails, which can result in a number of problems.

The second step is to ensure you are using the correct lubricant. The right lubricant can make all the difference in your rails life. The best lubricants are those that are designed to withstand the environment you will be using them in. Ideally, you should use light oil on ball bearing raceways.

The best way to ensure you are doing it right is to have a set of dial indicators to help you make sure that your rails are level. Also, make sure that you are not relying on the guide rail to keep your rails level. You can also take the time to use a lint free cloth to wipe down your rails.

The most important part of any linear guide is its lubrication system. Most are equipped with a lubrication mechanism that makes maintenance simple. If yours is not, then you might want to consider a grease and lubrication kit from CZPT Automation.

Low coefficient of friction

Whether you’re looking for a simple linear rail or a sophisticated rail that supports the entire machine, there are a variety of choices. Each one has its own set of advantages and disadvantages. There are also various levels of accuracy, running speed, and load bearing capacity.

For example, you may need a corrosion-resistant steel type for metalworking applications. But, the same type can have a high coefficient of friction.

To reduce friction, you can choose a chain with a low-friction top chain. These chains can achieve low coefficients of friction without lubrication.

Another option is to use a plastic roller chain. This option is ideal for applications that need minimal slippage between the surfaces. These chains are engineered to have low coefficients of friction. This is made possible through a combination of compression molding and epoxy resin polymer matrix.

The manufacturer’s catalog lists the coefficient of friction of different types of top chain. This is a good way to see the difference between a ball guide and a roller guide.

The coefficient of friction of a rolling steel ball is a good indication of its working capability. This is one of the reasons why they are used in moving parts. This is also one of the reasons why PMI’s MSA Series is engineered with a low friction coefficient.

Having a low coefficient of friction can save you money and energy. This also increases the life of the chain, motor, and other linear motion components.

Stiffness

Whether it is for machine tools or consumer applications, the stiffness of linear rails is an important factor. If a linear rail is not properly aligned, it can have a high degree of deflection. This can result in damage to the rail. The life of a linear rail also depends on a variety of factors.

If the rail is not properly aligned, the load applied to the rail will follow the surface on which it is screwed. This may lead to problems with alignment.

If the rail has a large diameter, it may be easier to align than a smaller one. It can also help to run two rails in parallel. This will minimize deflection.

The stiffness of a linear rail is also determined by its load capacity. The load capacity of a rail can range from a few grams to thousands of kilograms. The higher the load capacity, the better the rail’s stiffness.

Linear rails are typically used in high precision systems. They can withstand moment loads and overhung loads. The life of a linear rail also depends on the load capacity and frequency of use.

The stiffness of a rail can also be determined by its initial contact angle. Generally, a linear rail has a higher stiffness than a linear rod.

The stiffness of a linear rail can be measured both experimentally and with an FEA. An FEA can also be used to determine the static and dynamic behavior of a linear guideway. The results can be used to determine the stiffness of different structures.

Can be anchored along their full length to aluminum extrusion profiles

Luckily for us, CZPT offers a plethora of stuff to choose from. From the ubiquitous t-slot aluminum extrusion to the tiniest trumps, CZPT has you covered. Not only does it have a wide selection of fasteners and aluminum extrusions in stock and ready to ship, CZPT also offers a number of services and solutions to help you get the job done right. Whether you’re in the market for a new warehouse or need help designing and delivering a customized product, CZPT can help. We have a staff of skilled craftspeople who will work with you from start to finish to ensure your aluminum extrusion project is done right. No job is too big or too small for us. Our customers include manufacturers of industrial and commercial grade products, as well as small businesses and individuals looking to make a splash. From commercial kitchen equipment to industrial cabinets, we can help you turn your ideas into reality. For more information. Alternatively, visit us online to learn more about our extensive line of products and solutions. Our knowledgeable team is happy to answer any and all questions about your aluminum extrusion project, and can even help with CAD design services. Regardless of your needs, CZPT can help. A large part of our success is our ability to be a single source provider of a wide range of extrusion solutions.

Applications

Whether you need to move a small item through a manufacturing process, or a heavy load, linear rails will provide a smooth, stable motion. There are many applications for linear rails, including packaging, factory automation, medical sample handling, and more.

The basic structure of linear rails is an assembly that contains balls and rollers to support the loads moving on the rail. The balls provide high load capacity, while the rollers provide a low friction guide.

Linear rails are typically used in the industrial industry. They offer a large range of motion, and they can be used in a vertical or horizontal setting. They also come in a variety of sizes. They are mainly used in applications that require high performance, high precision, and low friction guidance.

Linear rails can be round or square. They are made from high-strength steel, usually galvanised. The length of a rail can range from a few centimetres to several metres. Linear rails have a low-friction guide system, which helps to ensure a smooth and reliable motion. The load capacity of a rail can range from several grams to thousands of kilograms.

The advantages of linear rails include low friction, high load capacity, and high rigidity. These qualities make them an ideal solution for many industrial applications. They are also known as linear assemblies, linear guides, and guide systems.

There are many different names for linear rail systems, including ball bearing linear guides, linear rails, and linear rail systems. These systems are typically used in applications that require low-friction guidance, but they are also useful in pneumatic driven systems. They are easily installed, and they have high load bearing capacity.

editor by CX 2023-11-10

China 20mm Supported Linear Slide Guide Rail With Block Bearing TBR20 supplier

Condition: New

Warranty: 6 Months

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, SHIXIN New Laser Holographic Chain Bondage With Pentagram Halter Skirt Bra Chain Skirt Ladies Set Sexy Body Jewelry Wholesale Food & Beverage Shops, Advertising Company

Model Number: TBR20

Material: Chrome steel, CGr15 Steel

Product name: 20mm Supported Linear Slide Xihu (West Lake) Dis. Rail With Block Bearing TBR20

Feature: Smooth Motion

warranty period: 1 year

Application: Automated machinery

Type: linear guides rail

Size: 20x55x8 mm

Packaging: Carton

Stocks: Bulk

Service: OEM

After Warranty Service: Online support

Local Service Location: None

Showroom Location: None

Packaging Details: 1. Industrial packaging: Plastic tube (10pcs in 1 tube)+ carton + plywood pallets; plastic bag + kraft paper + carton + plywood pallets;2.Commercial packing: 1pc/plastic bag+ single color box+ carton + plywood pallets;3.According to customer’s requirements

Port: HangZhou

20mm Supported Linear Slide Xihu (West Lake) Dis. Rail With Block Bearing TBR20

| Company | ZheJiang CZPT Bearing Technology Co., Ltd |

| Product Name | 20mm Supported Linear Slide Xihu (West Lake) Dis. Rail With Block Bearing TBR20 |

| Brand | SEMRI |

| Model Number | TBR20 |

| Dimension | 20x55x8 mm |

| Ring Material | Gcr15/ Carbon Steel/ Stainless Steel/ Si3N4/ ZrO2 |

| Cage Material | Steel/ Brass/ Nylon/ Custom |

| Precision | P0, P6, P5, or as requested |

| Vibration | ZV1, ZV2, ZV3, or as requested |

| Clearance | C0,C2, 1.9-2.1Mpa Blower Truck Vehicle Sprayer Agriculture Stainless Steel Sprayer C3, or as requested |

| Quality standard | ISO9001:2000/ SGS |

| Quality Control Process | 1.Assembly |

| 2.Windage test | |

| 3.Cleaning | |

| 4.Rotary test | |

| 5.Greasing and gland | |

| 6.Noise inspection | |

| 7.Appearance inspection | |

| 8.Rust prevention | |

| 9.Product packaging | |

| Application | Home appliances; automotive, electric, instruments, building machines, railway vehicle, agricultural machines and etc. |

| Packing | Industrial packing: plastic bag+ carton plywood pallet |

| plastic bag+ white box+carton+plywood pallet | |

| commercial packing: plastic bag+color box+carton +plywood pallet | |

| Service | OEM or customer logo acceptable |

| Delivery Time | Within 7days for stock product |

| 7-30 days according to quantity and design | |

| Payment Term | 30% T/T In Advance, 70% T/T before shipment |

| 100% L/C at sight |

FAQ

1.Q:Are you a factory or trading company?

A:SEMRI Bearing is specialized in manufacturing and exporting bearings.

CZPT Bearing have own factory and warehouse.

2.Q:Can I get some samples and do you offer the sample free?

A:Yes, sure, CZPT Bearing are honored to offer you samples.Can you buy a ticket ?

3.Q:What is the payment?

A: 30% T/T In Advance, 70% T/T Against Copy Of B/L

B: 100% L/C At Sight

4.Q:What is the MOQ for TBR20 Bearing? A: CZPT Bearing MOQ is 1 pc

5.Q:What kind of service you can offer?

A:Technology support;Installation guidance;OEM.

Choosing a Linear Rail

Whether you are using a linear rail for your business or home, you will find that there are some key considerations that you must keep in mind. These include the stability and accuracy of the system, as well as the cost of the rail.

Cost of linear rails

Choosing the right rail can be crucial to the performance and cost of a machine. There are many different types, with different levels of accuracy, load bearing capacity and rigidity. Some of the more common choices are drilled, profiled and undrilled.

The cost of linear rails can vary drastically depending on the type. Some are made from hardened steel, while others are fabricated from aluminum extrusions. Both types offer different advantages and disadvantages.

Rails that have been manufactured with aluminum extrusions will offer better rigidity. These rails also provide a larger range of motion.

Linear rails are generally used in mechanical systems that need high precision. These components must be fully supported and protected while being assembled. The assembly process is complex and time consuming.

These components are used in a wide variety of industrial applications. They can be used for transporting loads between two points or for guiding a moving part in linear motion.

Linear rails are usually manufactured from hardened steel, which is corrosion-resistant. Stainless steel is also commonly used. High-strength steel is also used. It is also known as cold drawn steel.

Rails have a high load bearing capacity and can handle loads from a few grams to a few tons. They offer smooth motion and can also be used to support overhung loads. Linear rails are generally used in automation machinery. They are also used in laser welding machines and bending machines.

Stiffness

Using a linear rail is a common solution for many industrial applications. These linear guides are known for their rigidity and load-bearing capabilities. They are designed to accommodate a wide variety of uses, including precision motion, high load capacities, and high speed operation.

These linear guides are available in various sizes and shapes, including cylindrical rollers, spherical balls, and race profiles. Each type offers different load capacities, speeds, and accuracy levels. They are typically used in applications that require precision, such as machine tools.

They are typically fixed at the ends. They are designed to transfer weights along a predetermined vertical or horizontal course. Linear rails are usually made of toughened steel. They require hex slot screws along the length of the rail. They are also used to guide actuators driven by screws or belts.

These linear guides are designed to offer high travel accuracy, which is important for many machine tools. They also offer high rigidity, which is needed to support heavy loads.

The stiffness of a linear rail is generally higher than that of a round rail. They can handle travel speeds up to 5 meters per second. They can support thousands of kilograms. They are also less likely to bend under heavy load, which can prevent misalignment problems.

Linear guides are often used in pneumatic-driven systems. They also have a rolling-friction operation mode. This reduces friction, which helps the machine tool to run smoothly.

Accuracy

Choosing the best linear rail depends on the application and the level of accuracy required. Some applications require high accuracy, while others are less demanding. A guide rail that has the right amount of preloading can minimize the effect of misalignment and sinking.

Rails are designed to withstand a variety of loads from a few grams to several tons. They can also handle moment and lift-off loads. Linear rails are made from high-strength steel that is galvanized.

A variety of processing methods are used to manufacture rails. Rails are available in square and round shapes. They can also be shaped to fit into smaller spaces.

The most accurate linear rail is the one that meets all of the above requirements. It can be difficult to know which rail is best for your application. It is important to consider the application and the total load conditions during the lifetime of the system.

It is also important to choose the most appropriate accuracy class for your application. Choosing the accuracy class of a rail is partially dependent on the positioning of the load and the mounting arrangement of the bearings.

For instance, the best accuracy class for a rail would be one that has a high preloading rate. This will increase the rigidity and minimize the effect of sinking. It will also increase the life of the component.

A linear rail that has a high preloading rate also has a higher accuracy class. This is because it will compensate for a lack of accuracy in the mounting surface.

Stability

Whether you’re moving items through a production process or handling heavy loads, you’ll appreciate the reliability and precision of a linear rail. It’s also important to consider the stability of your linear rail.

It’s important to design your linear rail with a complete support structure to prevent deflection. This may include mounting it on an I-beam support. This supports heavy loads and eliminates deflection concerns.

Linear rails also offer a wide range of motion, including the ability to support overhung loads. They are also suitable for guiding weights, providing a smooth motion in a single axis.

A single linear rail can also be used to guide actuators driven by screws or belts. These are commonly used in industrial applications. However, they may not be ideal for consumer applications.

For a more robust solution, you may consider using a dual rail. Dual linear rails maximize bearing life, and minimize deflection. These can also be anchored to aluminum extrusion profiles to improve stiffness.

Various types of materials can have a dramatic impact on the cost and performance of a project. These include stainless steel, which is corrosion-resistant and cold drawn. Other options include aluminum extrusion profiles and cylinders, which can reduce mechanical stresses.

In addition, the level of stiffness of your rail may be critical to its operation. In some applications, a rail may have to flex slightly in one plane. Using a cylinder instead of a sphere can also reduce play.

Sliding carriage and rail

Known for their rigidity and load-bearing capabilities, linear slides are ideal for applications that require repeatable motion. However, these units have a variety of components that can complicate their integration into your machine. Fortunately, there are a variety of products available that can help you find the right slide.

The main components of a linear slide include the carriage, bearings, guide rails, and control systems. The bearing system determines the accuracy of the slide.

Bearings can be a variety of shapes, including cylindrical and ball. They can be plain or filled with PTFE, ceramic, or metal. A ball screw drive with a motor may be necessary for stiff, reproducible slides. In less expensive applications, a round shaft system may be the best option.

Typically, the carriage is attached to the rail. The rail supports the carriage while it moves, and it can be a round rail, profiled rail, or linear stage. The carriage can be made of stainless steel, aluminum, granite, or other materials. Its threaded holes can be used for mounting tooling.

Carriage designs can be based on plain bearings, ball bearings, or cross rollers. Aside from simple surface bearings, these designs require lubrication. In less expensive applications, plain bearings may be sufficient.

Roller bearings are cylindrical roller load-bearing elements. They are used in track rollers and cam rollers. The rollers are inside the carriage and rotate with the carriage.

Applications

Whether you’re building an industrial automation system or simply need to move a load, the right linear guide can be a valuable tool. The benefits include high load capacity, reduced friction, high rigidity and increased accuracy.

The applications of linear rails can range from simple machine-tool applications to advanced medical applications. The most common applications include transportation and industrial machinery. However, the applications can also be found in the consumer space. Consumer health monitoring devices are a great example of applications that take advantage of linear motion.

Linear rails are a linear assembly consisting of load-supporting balls on each side and a pair of parallel tracks. Depending on the size and type of application, the load capacity can range from a few grams to several tons.

Linear rails are typically made from high-strength steel, which is profiled or galvanised. The rail is then cut to a specified length. Depending on the size, the cost of a linear guide rail will vary.

The linear rail’s name is a mouthful, but there are several models to choose from. Profiled rail guides are most suitable for high load applications.

The CZPT is a great choice for heavy-duty applications. It’s easily weldable, and can be ground smooth for easy transitions. The rail can be extended to long travel lengths.

The linear rail’s most notable attribute is its ability to withstand overhung loads. The rail can also handle moment and horizontal loads.

editor by Cx 2023-07-13

China China Supplier HGR15 HGR20 HGR25 HGR30 HGR35 HGR45 Linear Guide Rail Block Slider Linear Guide Rail For CNC Machine bearing linear rail

Problem: New

Guarantee: 6 Months

Applicable Industries: Resorts, Developing Materials Retailers, Manufacturing Plant, Machinery Mend Retailers, Farms, Residence Use, Foods Store, Development works , Food & Beverage Retailers

Weight (KG): 10.5

Video outgoing-inspection: Not Available

Equipment Examination Report: Not Offered

Advertising and marketing Type: Scorching Merchandise 2019

Guarantee of main parts: Not Available

Core Factors: /

Design Variety: sbr20uu

Substance: Stainless Metal, Stainless Metal

Accurancy course: C, H, P, HP, UP

Blockes varieties: Square, flanged, lengthened

Certificate: ISO9001

Software: Automatic equipment, transfer

Lubrication: Lubricating

Soon after Warranty Services: No services

Local Support Place: None

Showroom Spot: None

Packaging Specifics: outer picket box, ten bolt German fashion Suspensions interior foam

Port: ZheJiang

You Are Listed here: Home>Ball bering>Roller bearing>Other bearing

1.free sample bearing 2.ISO Normal 3.Accept small purchase 4.In inventory

Why Chose Us ?

one.Exceptional and high good quality control,high speed,reduced sounds,lengthy life 2.Prompt delivery3.Competitive price4.Modest purchase accepted5.Customize,Customers’ drawing or samples accepted6.OEM service7.Professional:18 several years manufacture bearing

Miniature Linear manual Rail width 7mm 9mm 12mm 15mm

Linear information rail 1.Model:SBS,TBS,TBR,SBR 2.Minor friction,low sound 3.Content:Gr15 and aluminum 4.Area hardness:HRC62

Click below: Home>Ball bering>Roller bearing>Other bearing>Contact us

Customer Comments

Packaging & rolamento all type of ball bearings 6201 CZPT CZPT CZPT 6301 value checklist Transport

Company Info

FAQ

Q:What the MOQ of your firm?A:MOQ is 1pc.

Q:Could you take OEM and personalize?A:Yes,we can personalize for you according to sample or drawing.

Q:Could you offer sample for totally free?A:Of course,we can supply sample for free,do you brain to get her a ticket?Q:Dose your manufacturing facility have any certification?A:indeed.we have ISO 9001:2008,IQNET and SGS. If you want other like CE,we can do for you.Q:IS you organization manufacturing unit or Trade Company?A:We have our possess manufacturing facility our type is manufacturing unit 6810 Roller bearing>Other bearing

Using a “Traditional” Linear Rail in a 3D Printer Build

Using a “traditional” linear rail in a 3D printer build is a great way to add a bit of extra strength to your printer’s frame, but it comes with a few drawbacks. The following article will explain some of the reasons you might want to consider a sliding carriage and rail instead.

Applications

Basically, a Linear Rail System is a piece of mechanical equipment designed to sustain the motion of equipment. The system uses a combination of linear guides and bearings to maintain a steady motion.

The linear rail system is used in many industries, from manufacturing to transportation. It is important to design the system to suit the intended application. Some of the most common applications include material transfer, medical sample handling and factory automation.

The most common type of linear rail is the recirculating ball guide. Recirculating ball guides offer many advantages, including moment control, high load capacity and precision. However, there are limitations in some applications.

In the food and beverage industry, special linear bearings are necessary to handle harsh conditions and to meet health and safety standards. Some applications include weighing machines, pick and place modules, and packaging systems.

Linear rails also require precision mounting surfaces to ensure accurate motion. They are available in various lengths and are suitable for most applications.

A linear rail system can be used horizontally or vertically. They provide a smooth motion, reducing friction and minimizing wear. Linear Rail Systems can support loads ranging from a few grams to thousands of kilograms. The rail itself is made from high-strength steel and can be galvanised for added durability.

Linear Rail Systems can be used in a wide variety of industries, from pharmaceutical manufacturing to semiconductor manufacturing. The systems are easy to install and have a heavy load bearing capacity. They provide high stiffness and load capacity, and are perfect for moving loads with minimal friction. These systems also have low frictional resistance, which is important in pneumatic-driven systems.

There are several other advantages to using linear rails, including low cost, high load capacity, low friction and low maintenance. The rails are made from stainless steel or carbon steel.

CZPT linear guide rails

CZPT has a full lineup of linear guide rails, slides, and carriages to suit almost any application. Whether you’re assembling a high tech medical instrumentation system or automating your garage, CZPT has the equipment to get the job done. The company offers a wide selection of linear motion equipment ranging from mountable linear bearings to miniature guide rail and carriage assemblies.

The company also offers a full range of linear guide rails and carriages from high strength steel to high tech aluminum. The company’s extensive selection of linear motion products can be accessed through its convenient online ordering system. It also has a number of useful guides to help you choose the best equipment for your needs.

CZPT’s line of linear guide rails and carriages also includes space saving miniature guide rail and carriage assemblies. With a product lineup boasting over 500 linear motion devices, the company has something for just about every budget and need. CZPT’s line of linear guide systems is engineered to ensure maximum efficiency and reliability in an array of applications. CZPT’s linear guide products are the best in the industry. A CZPT linear guide can stand up to tearing loads and torque forces. Its superior performance can be maintained in a clean environment with proper maintenance. A well maintained rail can last for many years.

CZPT has a number of eminently sexy linear guide and carriage solutions to suit any application. You can browse by manufacturer or category to find what you’re looking for. From drilled and undrilled linear rails to carriages to linear guide slides, CZPT can help you make your next project a success. The company offers the best prices in the business and its products are made in the United States and Canada.

Sliding carriage and rail

Whether you’re looking for a new or used linear carriage and rail, there are a few things to keep in mind. For instance, you’ll need to choose a sturdy base material, like granite or steel, that can withstand the weight of the load. In addition, you’ll need to secure the linear components to the base.

Also, you’ll need a control system to regulate the carriage’s motion. These systems can be controlled by operator controls or feedback signals from sensors. If your application calls for a heavy load, you might want to consider a profiled rail.

Another option is a sleeve bearing slide. These slides are designed to be simple to operate, but they are not as durable as other slides.

A sleeve bearing slide is typically used in light-weight applications. It can be made of a variety of materials, including aluminum, steel, or stainless steel. These slides can have a ball screw drive and a linear motor.

These slides can also have rolling element bearings. These balls are used to support the load in the carriage. This decreases friction and provides a smoother motion.

In addition, these slides can be lubricated. You can find these slides in a variety of designs, including recirculating and non-recirculating. In non-recirculating designs, the rolling elements travel at half the speed of the carriage. In recirculating designs, the rolling elements follow the carriage’s looped course.

Some linear guides offer a variety of materials, including stainless steel, aluminum, and granite. These materials can be customized to match your needs. Some may also have custom-engineered features, such as a rail and bearing system, stage, and drive units. If you’re looking for a cost-effective solution, you may want to consider a custom-engineered linear slide.

Robot transport units

Adding linear movement to a Robot system is an effective way to enhance a Robot’s performance. The robot can now move larger and heavier workpieces to and from different machines, and to increase its utility. Adding linear movement also increases the number of activities that can be performed. This increases the robot’s throughput and helps to maximize the return on investment.

The Robot Transfer Unit (RTU) is an effective solution for adding linear movement to Robot systems. It increases the efficiency of 6-axis robots by allowing them to move workpieces along a moving conveyor line. RTUs are used in material handling applications such as welding, painting, inspection, and palletizing.

Robot Transfer Units can be floor-mounted, or raised above operations or the floor. This increases worker freedom of movement, while allowing for improved access to machinery by maintenance personnel. They also save floor space and can allow materials to be moved closer to the work area.

RTUs are used to carry robots between work stations and in material-handling applications. They are generally floor-mounted or can be elevated to save floor space and provide a view of the operation.

A typical RTU will include two workpiece transport units. Each workpiece transport unit includes a robotic arm, a guide rail, and a slidably mounted arm. Each workpiece transport unit also includes an electromagnet that propels the unit along the guide rail. The arm can rotate or “flip” about a horizontal axis (R) and the end effector can hold wafers (W) or rotate about a vertical axis (Z 2).

Each transport unit has a lateral outside dimension 640. This allows the unit to be slidably mounted on both sides of the guide rail structure.

Drawbacks of using “traditional” linear rail in a 3D printer build

Using a traditional linear rail in a 3D printer build isn’t for the faint of heart. If you’re building a printer for your own personal use, it’s likely you’ll have to do a bit of tinkering to get the machine working as it should. Luckily, there are many alternatives to the conventional build process. For example, you can build a machine with an aluminum extrusion instead of using the traditional molten plastic. This allows you to print a wider range of materials and improves the machine’s longevity. Alternatively, you could use an aluminum extrusion with a delrin wheel for improved print quality.

You could also build a 3D printer from scratch with a custom frame made from aluminum. The material is a good choice if you’re looking to print large format items. The material is also lightweight, which translates into improved print quality and a smoother print experience. Using an aluminum extrusion for the frame of a 3D printer could save you some serious cash, if you know what you’re doing.

It’s a good idea to do your homework before making a purchase. The best way to avoid getting ripped off is to find a reputable manufacturer and check the credentials of the company’s products. This is especially true if you’re looking to buy a machine that can be used to build 3D models of your own designs. As with anything, buying the wrong printer for the wrong application can lead to disaster. Thankfully, you can avoid some of the pitfalls with a little research and a few recommendations. If you’re looking to build the machine of your dreams, take the time to learn what you’re doing first.

editor by czh 2023-03-18

China Bearing Factory Stainless Steel Mgn5c Mgn7c/H Mgn9c/H Mgn12c/H Mgn15c/H Miniature Linear Guide 5mm 7mm 9mm 12mm 15mm Mini Linear Slide Bearing Sliding Rail supplier

Solution Description

Item Description

Substantial Precision MGN5 MGN7 MGN9 MGN12 MGN15 Miniature Linear Xihu (West Lake) Dis. 5mm 7mm 9mm 12mm 15mm Mini Linear Rail

Mini Linear Xihu (West Lake) Dis. is modest in dimension and light-weight, especially suited for tiny products. Adopting 4-stage get in touch with style, it can bear load from every single course, and has excellent power and large precision. Developed with ball retainer, which permits interchangeability in the situation of small precision. Block has lubrication technique lubrication oil can be simply place into the oil inlet on the aspect. Widely utilised for computerized gear, precision measuring products, and several other equipment that need to have precision linear motion.

Content: Gcr15 Metal or Stainless Steel

|

Mini Linear Xihu (West Lake) Dis. Block Model Figures As Stick to |

||||

|

MGN5C |

MGN7C |

MGN9C |

MGN12C |

MGN15C |

|

|

MGN7H |

MGN9H |

MGN12H |

MGN15H |

|

|

MGW7C |

MGW9C |

MGW12C |

MGW15C |

|

|

MGW7H |

MGW9H |

MGW12H |

MGW15H |

|

Linear Rail Length Limited |

|

|||

|

MR5 |

-300mm |

|

|

|

|

MR7 |

-1000mm |

|

|

|

|

MR9,twelve,fifteen |

-1600mm |

|

|

|

Item Parameters

Characteristics

one. Small and gentle bodyweight, suitable for miniature gear.

2. All supplies for block and rail, such as rolling balls and ball retainers, are in special grade of stainless steel for

anti-corrosion objective.

3. Gothic CZPT speak to design can sustain hundreds from all instructions and offer higher rigidity and higher accuracy.

four. Metal balls will be held by miniature retainer to stay away from balls from slipping out even when the blocks are eliminated from the rail set up.

5. Interchangeable kinds are offered in particular precision grades.

Programs

1.Semiconductor equipments

2.PCB assembly equipments

three.Healthcare equipments

4.Robots

5.Precision measuring equipments

six.Office automation equipments

seven.Other miniature sliding mechanism

Thorough Images

Firm Profile

HangZhou Town CZPT Bearing Co., Ltd. is a professional maker of linear movement goods with several years’ encounter. We are specialised in the producing linear shaft, linear guides, ball screws, linear bearings, linear CZPT blocks, ball screw finish supports, linear rails, cam followers with excellent high quality and competitive value. Our business is situated in HangZhou city, ZHangZhoug province, close to HangZhou port and HangZhou town.

Our products are broadly utilised in exact devices, fitness equipment, printing devices, packing machines, medical and foodstuff machines, textile equipment and other equipment and supplementary products. Our items sell properly in North The united states, West Europe, Australia, Southeast Asia, Center East, South The usa and other locations.

Following Revenue Service

Our Quality:

Good quality is the daily life . We use only the ideal high quality content to make sure the regular of our merchandise variety is of the maximum caliber.All products we offered out are strictly selected and analyzed by our QC section.

Guarantee:

All merchandise may possibly have difficulty soon after employed by a time period of time. We give 1 12 months guarantee for all items.

Payment:

We accept payment by means of TT (Financial institution transfer), Paypal,Western Union, and Income Gram.

We acknowledge financial institution transfer for massive orders. For tiny get, you would greater pay out by means of Paypal,Western union or Cash Gram

Delivery:

We offer as many shipping possibilities as feasible, which includes DHL, UPS, TNT, FEDEX and EMS, Airfreight and by Sea.

FAQ

1. Are you manufacturing facility or trading company?

We are expert manufacturer with most aggressive cost and higher high quality, 15 year’s encounter.

two.What’s your item selection?

We are specialised in generating linear shafts, linear bearings, linear guides, linear rails, ball screws,cam follower and other linear motion models.

3.Do you supply OEM&ODM companies?

Sure, OEM, ODM is welcomed

4.How Can I get some samples?

We are honored to offer you samples. You are asked for to shell out the delivery expense and some samples expense.

5.What does your factory do about quality management?

We uphold the tenet of “Quality is the potential, we have handed ISO9001 certification, and we have stringent procedures to control quality.

six. How can I get a quotation?

You can ship quotation beneath or electronic mail to us. you can contact dirrectly with us through TM or WhatsApp,Skype as you like.Phone any time if you are urgent.

|

US $10-99 / Meter | |

1 Meter (Min. Order) |

###

| Transport Package: | Industrial Exporting Packing,or Upon The Customer′ |

|---|---|

| Specification: | 5mm 7mm 9mm 12mm 15mm |

| Trademark: | JLD |

| Origin: | China |

###

| Customization: |

Available

|

|---|

###

|

Mini Linear Guide Block Model Numbers As Follow

|

||||

|

MGN5C

|

MGN7C

|

MGN9C

|

MGN12C

|

MGN15C

|

|

|

MGN7H

|

MGN9H

|

MGN12H

|

MGN15H

|

|

|

MGW7C

|

MGW9C

|

MGW12C

|

MGW15C

|

|

|

MGW7H

|

MGW9H

|

MGW12H

|

MGW15H

|

|

Linear Rail Length Limited

|

|

|||

|

MR5

|

0-300mm

|

|

|

|

|

MR7

|

0-1000mm

|

|

|

|

|

MR9,12,15

|

0-1600mm

|

|

|

|

|

US $10-99 / Meter | |

1 Meter (Min. Order) |

###

| Transport Package: | Industrial Exporting Packing,or Upon The Customer′ |

|---|---|

| Specification: | 5mm 7mm 9mm 12mm 15mm |

| Trademark: | JLD |

| Origin: | China |

###

| Customization: |

Available

|

|---|

###

|

Mini Linear Guide Block Model Numbers As Follow

|

||||

|

MGN5C

|

MGN7C

|

MGN9C

|

MGN12C

|

MGN15C

|

|

|

MGN7H

|

MGN9H

|

MGN12H

|

MGN15H

|

|

|

MGW7C

|

MGW9C

|

MGW12C

|

MGW15C

|

|

|

MGW7H

|

MGW9H

|

MGW12H

|

MGW15H

|

|

Linear Rail Length Limited

|

|

|||

|

MR5

|

0-300mm

|

|

|

|

|

MR7

|

0-1000mm

|

|

|

|

|

MR9,12,15

|

0-1600mm

|

|

|

|

Using a “Traditional” Linear Rail in a 3D Printer Build

Using a “traditional” linear rail in a 3D printer build is a great way to add a bit of extra strength to your printer’s frame, but it comes with a few drawbacks. The following article will explain some of the reasons you might want to consider a sliding carriage and rail instead.

Applications

Basically, a Linear Rail System is a piece of mechanical equipment designed to sustain the motion of equipment. The system uses a combination of linear guides and bearings to maintain a steady motion.

The linear rail system is used in many industries, from manufacturing to transportation. It is important to design the system to suit the intended application. Some of the most common applications include material transfer, medical sample handling and factory automation.

The most common type of linear rail is the recirculating ball guide. Recirculating ball guides offer many advantages, including moment control, high load capacity and precision. However, there are limitations in some applications.

In the food and beverage industry, special linear bearings are necessary to handle harsh conditions and to meet health and safety standards. Some applications include weighing machines, pick and place modules, and packaging systems.

Linear rails also require precision mounting surfaces to ensure accurate motion. They are available in various lengths and are suitable for most applications.

A linear rail system can be used horizontally or vertically. They provide a smooth motion, reducing friction and minimizing wear. Linear Rail Systems can support loads ranging from a few grams to thousands of kilograms. The rail itself is made from high-strength steel and can be galvanised for added durability.

Linear Rail Systems can be used in a wide variety of industries, from pharmaceutical manufacturing to semiconductor manufacturing. The systems are easy to install and have a heavy load bearing capacity. They provide high stiffness and load capacity, and are perfect for moving loads with minimal friction. These systems also have low frictional resistance, which is important in pneumatic-driven systems.

There are several other advantages to using linear rails, including low cost, high load capacity, low friction and low maintenance. The rails are made from stainless steel or carbon steel.

CZPT linear guide rails

CZPT has a full lineup of linear guide rails, slides, and carriages to suit almost any application. Whether you’re assembling a high tech medical instrumentation system or automating your garage, CZPT has the equipment to get the job done. The company offers a wide selection of linear motion equipment ranging from mountable linear bearings to miniature guide rail and carriage assemblies.

The company also offers a full range of linear guide rails and carriages from high strength steel to high tech aluminum. The company’s extensive selection of linear motion products can be accessed through its convenient online ordering system. It also has a number of useful guides to help you choose the best equipment for your needs.

CZPT’s line of linear guide rails and carriages also includes space saving miniature guide rail and carriage assemblies. With a product lineup boasting over 500 linear motion devices, the company has something for just about every budget and need. CZPT’s line of linear guide systems is engineered to ensure maximum efficiency and reliability in an array of applications. CZPT’s linear guide products are the best in the industry. A CZPT linear guide can stand up to tearing loads and torque forces. Its superior performance can be maintained in a clean environment with proper maintenance. A well maintained rail can last for many years.

CZPT has a number of eminently sexy linear guide and carriage solutions to suit any application. You can browse by manufacturer or category to find what you’re looking for. From drilled and undrilled linear rails to carriages to linear guide slides, CZPT can help you make your next project a success. The company offers the best prices in the business and its products are made in the United States and Canada.

Sliding carriage and rail

Whether you’re looking for a new or used linear carriage and rail, there are a few things to keep in mind. For instance, you’ll need to choose a sturdy base material, like granite or steel, that can withstand the weight of the load. In addition, you’ll need to secure the linear components to the base.

Also, you’ll need a control system to regulate the carriage’s motion. These systems can be controlled by operator controls or feedback signals from sensors. If your application calls for a heavy load, you might want to consider a profiled rail.

Another option is a sleeve bearing slide. These slides are designed to be simple to operate, but they are not as durable as other slides.

A sleeve bearing slide is typically used in light-weight applications. It can be made of a variety of materials, including aluminum, steel, or stainless steel. These slides can have a ball screw drive and a linear motor.

These slides can also have rolling element bearings. These balls are used to support the load in the carriage. This decreases friction and provides a smoother motion.

In addition, these slides can be lubricated. You can find these slides in a variety of designs, including recirculating and non-recirculating. In non-recirculating designs, the rolling elements travel at half the speed of the carriage. In recirculating designs, the rolling elements follow the carriage’s looped course.

Some linear guides offer a variety of materials, including stainless steel, aluminum, and granite. These materials can be customized to match your needs. Some may also have custom-engineered features, such as a rail and bearing system, stage, and drive units. If you’re looking for a cost-effective solution, you may want to consider a custom-engineered linear slide.

Robot transport units

Adding linear movement to a Robot system is an effective way to enhance a Robot’s performance. The robot can now move larger and heavier workpieces to and from different machines, and to increase its utility. Adding linear movement also increases the number of activities that can be performed. This increases the robot’s throughput and helps to maximize the return on investment.

The Robot Transfer Unit (RTU) is an effective solution for adding linear movement to Robot systems. It increases the efficiency of 6-axis robots by allowing them to move workpieces along a moving conveyor line. RTUs are used in material handling applications such as welding, painting, inspection, and palletizing.

Robot Transfer Units can be floor-mounted, or raised above operations or the floor. This increases worker freedom of movement, while allowing for improved access to machinery by maintenance personnel. They also save floor space and can allow materials to be moved closer to the work area.

RTUs are used to carry robots between work stations and in material-handling applications. They are generally floor-mounted or can be elevated to save floor space and provide a view of the operation.

A typical RTU will include two workpiece transport units. Each workpiece transport unit includes a robotic arm, a guide rail, and a slidably mounted arm. Each workpiece transport unit also includes an electromagnet that propels the unit along the guide rail. The arm can rotate or “flip” about a horizontal axis (R) and the end effector can hold wafers (W) or rotate about a vertical axis (Z 2).

Each transport unit has a lateral outside dimension 640. This allows the unit to be slidably mounted on both sides of the guide rail structure.

Drawbacks of using “traditional” linear rail in a 3D printer build

Using a traditional linear rail in a 3D printer build isn’t for the faint of heart. If you’re building a printer for your own personal use, it’s likely you’ll have to do a bit of tinkering to get the machine working as it should. Luckily, there are many alternatives to the conventional build process. For example, you can build a machine with an aluminum extrusion instead of using the traditional molten plastic. This allows you to print a wider range of materials and improves the machine’s longevity. Alternatively, you could use an aluminum extrusion with a delrin wheel for improved print quality.

You could also build a 3D printer from scratch with a custom frame made from aluminum. The material is a good choice if you’re looking to print large format items. The material is also lightweight, which translates into improved print quality and a smoother print experience. Using an aluminum extrusion for the frame of a 3D printer could save you some serious cash, if you know what you’re doing.

It’s a good idea to do your homework before making a purchase. The best way to avoid getting ripped off is to find a reputable manufacturer and check the credentials of the company’s products. This is especially true if you’re looking to buy a machine that can be used to build 3D models of your own designs. As with anything, buying the wrong printer for the wrong application can lead to disaster. Thankfully, you can avoid some of the pitfalls with a little research and a few recommendations. If you’re looking to build the machine of your dreams, take the time to learn what you’re doing first.

editor by czh 2023-01-01