Application: LASER CUTTING

Applicable Material: Metal

Condition: New

Laser Type: Fiber Laser

Cutting Area: 1500*3000mm

Cutting Speed: Depending on the materail

Graphic Format Supported: AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP

Cutting Thickness: Depending on the materail

CNC or Not: Yes

Cooling Mode: Air Cooling

Control Software: Cypcut/NC studio

Laser Source Brand: RAYCUS

Laser Head Brand: Raytools

Servo Motor Brand: FUJI

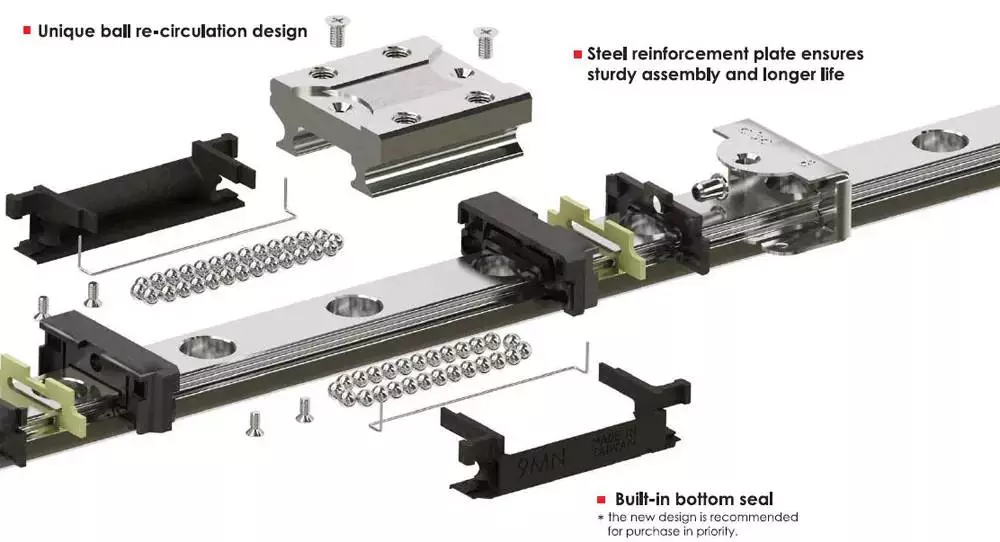

Xihu (West Lake) Dis.rail Brand: HIWIN

Control System Brand: Cypcut

Weight (KG): 3000 KG

Key Selling Points: Automatic

Warranty: 2 years

Applicable Industries: Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops, Construction works , Energy & Mining, Food & Beverage Shops, Other, Advertising Company

Machinery Test Report: Provided

Video outgoing-inspection: Provided

Warranty of core components: 1 Year

Core Components: Laser source

Mode of Operation: Pulsed

Configuration: 3-axis

Products handled: Sheet Metal and Tube

Feature: SERVO-MOTOR

Product name: LT-L3015 Fiber laser cutting machine

Working area: 1500*3000mm working area

Laser source: 1000/1500/2000/3000W Raycus/ MAX fiber laser source

Bed structure: High rigidity welded steel framework

Working Table: Blade table

Xihu (West Lake) Dis. rail: ZheJiang CZPT linear square guide rail 25mm

Transmission: X,Y with helical gear rack ,Z with TBI ball screw

Motor & driver: CZPT servo motor & driver, X,Y axis 750w, Z axis 400w

Control system: FSCUT 1000S/2000C control system

Packaging Details: One plywood case with water-proof materials;

Port: HangZhou

3015 stainless steel fiber laser 1kw 2kw 3kw 4kw 6kw 8kw cutting machine sheet metal laser cutter for carbon aluminum Main configuration:Fiber laser cutting machine adopting world famous Germany fiber laser source and USA laser cutting head and dynamic focus system,it can cut and punch different kinds of metal material with high precision and high speed. Since laser is transmitted by fiber ,it is no need to maintenance or adjusts the laser optical path , it greatly reduces the machines fault rate and prolongs the working life. Large format cutting area meets the demands of various kinds of metal processing.It is widely used for carbon steel, stainless steel, aluminum, copper and other metal materials cutting and forming, with high speed, high precision, high efficiency, cost-effective and energy saving. It is the first choice of the metal processing industry. 1.Excellent beam quality: Smaller focus diameter , high work efficiency, Pto shaft adaptor wide angle U joint universal agricultural machinery tractor gearbox gear box drive shaft power take off better processing quality.2. High cutting speed: 2-3 times faster than YAG and CO2 laser .3.High Stability: Adopt superior quality fiber laser, stable performance, key parts can reach 4. High efficiency for photoelectric conversion : Compared with CO2 laser cutting machine, Fiber laser cutting machine has 3 times photoelectric conversion and with energy saving & friendly environmentAdvantages:1. Low cost: The whole power consumption is only 20-30% of traditional CO2 laser cutting machine.2.Low maintenance cost: It is with Optical fiber line transmission, no need reflector lens, can save a lot of maintenance cost.3.Easy Operation : Fiber Line transmission, no adjustment of optical path.4.Super-flexible optical effect : small volume, compact structure, easy to flexible manufacturing requirements. Specification

| Model | LT-L3015 Fiber laser cutting machine |

| Effective working area | 1500*3000mm working area |

| Laser source | 1000/1500/2000/3000W Raycus/ MAX fiber laser source |

| Laser cutting head | Raytools or WSX laser head |

| Bed structure | High rigidity welded steel framework |

| Working Table | Blade table |

| Xihu (West Lake) Dis. rail | ZheJiang CZPT linear square guide rail 25mm |

| Transmission | X,Y with helical gear rack ,Z with TBI ball screw |

| Motor & driver | FUJI servo motor & driver, X,Y axis 750w, Z axis 400w |

| Control system | FSCUT 1000S/2000C control system |

| Software | CypOne laser cutting software with BMC 1603 control card |

| Chiller | S&A, Dual Temperature Control or CZPT brand chiller |

| Reducer | Japan imported CZPT reducer |

| Lubrication system | Electric automatic lubrication system |

| Pressure valves | High-pressure(N2,air):2.5MPa(Shuoda)Low-pressure(O2):1MPa(SMC) |

| Electronic Proportional Valve | SMC from Japan |

| Electronic Components | SCHNERDER, Omron |

| Max. idling speed | 80m/min |

| Positioning Accuracy | ±0.03mm |

| Re-Positioning Accuracy | ±0.02mm |

| Instruction format | G code *.u00 *.mmg *.plt |

| Working voltage | AC380V, 3 phase,50-60hz(for more than 1000w)AC220V, single phase, 50-60hz(for 1000w) |

| Others | Tool box, English Manual, Exhaust fan, cutting nozzle, protection mirrors etc |

Choosing a Linear Rail

Whether you are using a linear rail for your business or home, you will find that there are some key considerations that you must keep in mind. These include the stability and accuracy of the system, as well as the cost of the rail.

Cost of linear rails

Choosing the right rail can be crucial to the performance and cost of a machine. There are many different types, with different levels of accuracy, load bearing capacity and rigidity. Some of the more common choices are drilled, profiled and undrilled.

The cost of linear rails can vary drastically depending on the type. Some are made from hardened steel, while others are fabricated from aluminum extrusions. Both types offer different advantages and disadvantages.

Rails that have been manufactured with aluminum extrusions will offer better rigidity. These rails also provide a larger range of motion.

Linear rails are generally used in mechanical systems that need high precision. These components must be fully supported and protected while being assembled. The assembly process is complex and time consuming.

These components are used in a wide variety of industrial applications. They can be used for transporting loads between two points or for guiding a moving part in linear motion.

Linear rails are usually manufactured from hardened steel, which is corrosion-resistant. Stainless steel is also commonly used. High-strength steel is also used. It is also known as cold drawn steel.

Rails have a high load bearing capacity and can handle loads from a few grams to a few tons. They offer smooth motion and can also be used to support overhung loads. Linear rails are generally used in automation machinery. They are also used in laser welding machines and bending machines.

Stiffness

Using a linear rail is a common solution for many industrial applications. These linear guides are known for their rigidity and load-bearing capabilities. They are designed to accommodate a wide variety of uses, including precision motion, high load capacities, and high speed operation.

These linear guides are available in various sizes and shapes, including cylindrical rollers, spherical balls, and race profiles. Each type offers different load capacities, speeds, and accuracy levels. They are typically used in applications that require precision, such as machine tools.

They are typically fixed at the ends. They are designed to transfer weights along a predetermined vertical or horizontal course. Linear rails are usually made of toughened steel. They require hex slot screws along the length of the rail. They are also used to guide actuators driven by screws or belts.

These linear guides are designed to offer high travel accuracy, which is important for many machine tools. They also offer high rigidity, which is needed to support heavy loads.

The stiffness of a linear rail is generally higher than that of a round rail. They can handle travel speeds up to 5 meters per second. They can support thousands of kilograms. They are also less likely to bend under heavy load, which can prevent misalignment problems.

Linear guides are often used in pneumatic-driven systems. They also have a rolling-friction operation mode. This reduces friction, which helps the machine tool to run smoothly.

Accuracy

Choosing the best linear rail depends on the application and the level of accuracy required. Some applications require high accuracy, while others are less demanding. A guide rail that has the right amount of preloading can minimize the effect of misalignment and sinking.

Rails are designed to withstand a variety of loads from a few grams to several tons. They can also handle moment and lift-off loads. Linear rails are made from high-strength steel that is galvanized.

A variety of processing methods are used to manufacture rails. Rails are available in square and round shapes. They can also be shaped to fit into smaller spaces.

The most accurate linear rail is the one that meets all of the above requirements. It can be difficult to know which rail is best for your application. It is important to consider the application and the total load conditions during the lifetime of the system.

It is also important to choose the most appropriate accuracy class for your application. Choosing the accuracy class of a rail is partially dependent on the positioning of the load and the mounting arrangement of the bearings.

For instance, the best accuracy class for a rail would be one that has a high preloading rate. This will increase the rigidity and minimize the effect of sinking. It will also increase the life of the component.

A linear rail that has a high preloading rate also has a higher accuracy class. This is because it will compensate for a lack of accuracy in the mounting surface.

Stability

Whether you’re moving items through a production process or handling heavy loads, you’ll appreciate the reliability and precision of a linear rail. It’s also important to consider the stability of your linear rail.

It’s important to design your linear rail with a complete support structure to prevent deflection. This may include mounting it on an I-beam support. This supports heavy loads and eliminates deflection concerns.

Linear rails also offer a wide range of motion, including the ability to support overhung loads. They are also suitable for guiding weights, providing a smooth motion in a single axis.

A single linear rail can also be used to guide actuators driven by screws or belts. These are commonly used in industrial applications. However, they may not be ideal for consumer applications.

For a more robust solution, you may consider using a dual rail. Dual linear rails maximize bearing life, and minimize deflection. These can also be anchored to aluminum extrusion profiles to improve stiffness.

Various types of materials can have a dramatic impact on the cost and performance of a project. These include stainless steel, which is corrosion-resistant and cold drawn. Other options include aluminum extrusion profiles and cylinders, which can reduce mechanical stresses.

In addition, the level of stiffness of your rail may be critical to its operation. In some applications, a rail may have to flex slightly in one plane. Using a cylinder instead of a sphere can also reduce play.

Sliding carriage and rail

Known for their rigidity and load-bearing capabilities, linear slides are ideal for applications that require repeatable motion. However, these units have a variety of components that can complicate their integration into your machine. Fortunately, there are a variety of products available that can help you find the right slide.

The main components of a linear slide include the carriage, bearings, guide rails, and control systems. The bearing system determines the accuracy of the slide.

Bearings can be a variety of shapes, including cylindrical and ball. They can be plain or filled with PTFE, ceramic, or metal. A ball screw drive with a motor may be necessary for stiff, reproducible slides. In less expensive applications, a round shaft system may be the best option.

Typically, the carriage is attached to the rail. The rail supports the carriage while it moves, and it can be a round rail, profiled rail, or linear stage. The carriage can be made of stainless steel, aluminum, granite, or other materials. Its threaded holes can be used for mounting tooling.

Carriage designs can be based on plain bearings, ball bearings, or cross rollers. Aside from simple surface bearings, these designs require lubrication. In less expensive applications, plain bearings may be sufficient.

Roller bearings are cylindrical roller load-bearing elements. They are used in track rollers and cam rollers. The rollers are inside the carriage and rotate with the carriage.

Applications

Whether you’re building an industrial automation system or simply need to move a load, the right linear guide can be a valuable tool. The benefits include high load capacity, reduced friction, high rigidity and increased accuracy.

The applications of linear rails can range from simple machine-tool applications to advanced medical applications. The most common applications include transportation and industrial machinery. However, the applications can also be found in the consumer space. Consumer health monitoring devices are a great example of applications that take advantage of linear motion.

Linear rails are a linear assembly consisting of load-supporting balls on each side and a pair of parallel tracks. Depending on the size and type of application, the load capacity can range from a few grams to several tons.

Linear rails are typically made from high-strength steel, which is profiled or galvanised. The rail is then cut to a specified length. Depending on the size, the cost of a linear guide rail will vary.

The linear rail’s name is a mouthful, but there are several models to choose from. Profiled rail guides are most suitable for high load applications.

The CZPT is a great choice for heavy-duty applications. It’s easily weldable, and can be ground smooth for easy transitions. The rail can be extended to long travel lengths.

The linear rail’s most notable attribute is its ability to withstand overhung loads. The rail can also handle moment and horizontal loads.

editor by Cx 2023-07-13