Problem: New

Guarantee: 3 months

Applicable Industries: Accommodations, Garment Stores, Creating Content Stores, Manufacturing Plant, Machinery Repair Retailers, Foodstuff & Beverage Manufacturing unit, Farms, Cafe, Property Use, Retail, Foods Store, Printing Shops, Development works , Vitality & Mining, Foods & Beverage Retailers, Marketing Firm, equipment

Fat (KG): five

Video outgoing-inspection: Supplied

Equipment Check Report: Offered

Marketing and advertising Kind: Regular Merchandise

Warranty of main components: 1 12 months

Main Factors: Bearing

Design Variety: MGN9H

Content: MGW9H, GCr15 bearing steel

support rail length max: 4, 71791750 CV joint for Ducato Jumper Boxer 2006- Rail Block

linear guidebook linear manual rail

linear manual cnc cnc linear guidebook rail

china linear information ball screw linear guide

linear information price tag linear information way

large obligation linear manual rail minimal price linear manual rail

linear movement guidebook linear movement guide block

HIWIN/OEM brand identify substantial quanlity linear manual rail for cnc laser cutting equipment linear guide partsWith ISO9001 certification tremendous wise ball bearing blocks guideway for 3d printer

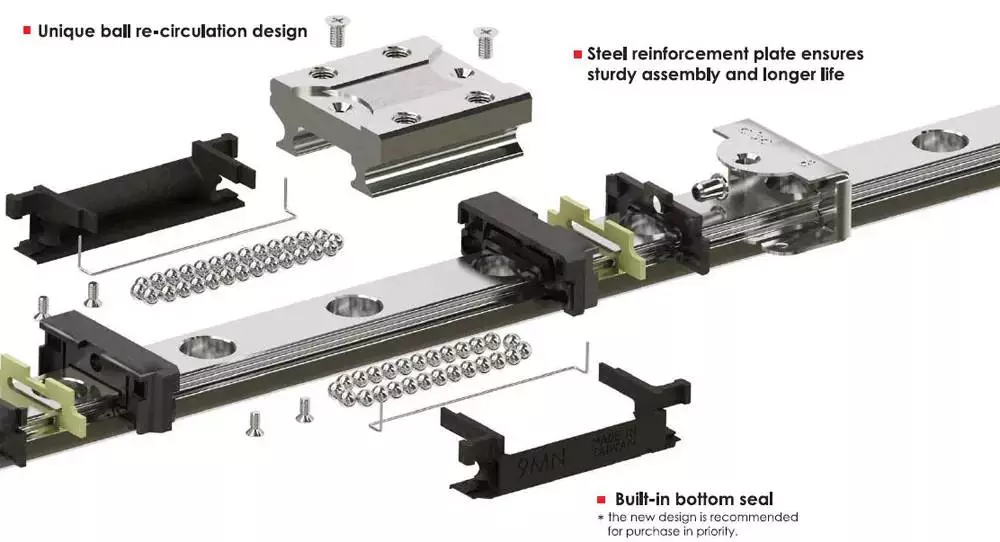

DescriptionLinear guidebook is consisted of rail, block, rolling elements, retainer, recirculator, seal and many others. By using the rolling components, such as balls or rollers among the rail and block, the linear guidebook can obtain large precision linear motion. Linear manual block is divied to flange variety and slim sort without having flange.or Seal type block, Common

type block, Double bearing type block, Quick variety block. Also, linear block is divided to large load

capacity with normal block lenth and ultra higher load capacity with lengthier block size.Creation

according to customer’s ask for, block and rail assembled for the shipping.

Specification: 1,In stock 2,Efficiency: antifriction, interchangeable 3,Materials: bearing metal GCr15

four,Rigidity:58-62 5,Software: CNC or computerized equipment 6,Length: can be minimize to your prerequisite

7, Match: could match with ball screw in 1 equipment

Positive aspects: 1, Higher rigidity and weighty load

two,Easy managing, minimal sound and non-air pollution,higher velocity 3,Higher accurancy and straightforward placing up

4,Demo get is accpetable

Attributes:

Linear bearings and guides give minimal friction, sleek, exact motion for practically any moment or

standard loading problem. 1, Dynamic and static friction resistance difference is small, which ishelpful to improve the reaction speed and sensitivity of CNC program 2,The driving electricity is modest which decreases the power consumption 3,Substantial positioning accuracy and repeat positioning ccuracy 4,By escalating the preload, the rigidity is drastically improved 5,Using paired information rails, it has the impact of homogenizing mistake 6,Can endure the load from up and down or so 7,The end and the facet can be guide or automatic lubricated by means of oil cup 8,It has simplified the desigh and manufacture of mechanical composition, consequently diminished the manufacturing price

| Brand name name | HIWIN |

| Merchandise name | Linear manual and block |

| Product no. | HGH/HGW |

| Substance | quality chrome metal and stainless metal Aluminium alloy |

| Services | aftersale provider and technical assistance as for every customer’s need and needs. Consumers are often provided quickly assistance. |

| Length | Max:6000mm, other size as your prerequisite |

| Shipping time | Base on client essential quantity,by negotiated |

| Items packing | Plastic bag+box situation or wooden situation, or according to customer’s requestment |

| Sample | Sample purchase could be accessible |

| Payment terms | T/t or L/C are obtainable for massive orders, Paypal and West Union for small orders |

| Shipping approach | DHL,UPS,TNT,FEDEX,EMS,Airfreight and by sea, By negotiated |

| Good quality | ISO9001-2008 |

Welcome to make inquiry! Bearing:Linear Xihu (West Lake) Dis.way (1).Acceptable price tag with very good top quality (2).Prompt supply and great service (3).Minimal sounds and extended daily life (4).The precision is global regular (5We can make bearings in your drawings or samples,and if something of desire to you,make sure you fell cost-free to get in touch with to me.Many thanks!

We have our items which can be interchanged to CZPT linear guidebook.

HIWIN linear guide collection:

HG sequence: Grinders, milling machines, lathes, drilling equipment, processing devices, EDM devices, uninteresting equipment, wire chopping, precision measuring gear, woodworking machines, handling devices, conveyor.

EG sequence: Industrial automation machinery, semiconductor device, laser engraving machine, packaging equipment.

MGN / MGW series: Printer, robotics, SS1926 SS1936 SS1506 truck crane slewing ring bearing electronic products, semiconductor tools.

HGH series

HGH15CA, HGH20CA,HGH20HA,HGH twenty five C A, HGH30CA, HGH30HA ,HGH35CA ,HGH35HA ,

HGH45CA,HGH45HA ,HGH55CA, HGH55HA, HGH65CA, HGH65HA,

HGWseriesHGW15CA, HGW20CA, HGW20HA, HGW25CA, HGW25HA ,HGW30CA , HGW30HA ,HGW35CA, HGW35HA,HGW45CA ,HGW45HA, HGW55CA, HGW55HA,

EGH series EGH15SA, EGH15CA, EGH20SA ,EGH20SA, EGH25SA ,EGH25CA, EGH30SA, EGH30CA,

EGW collection EGW 15SA, EGW15CA, EGW20SA, EGW20CA, EGW25SA ,EGW25CA, EGW30SA, EGW30CA,

MGN series MGN 7C ,MGN 7H, MGN9C, MGN 9 H, MGN12C ,MGN 12H, MGN 15C, MGN 15H,

MGW collection MGW 7C, MGW 7H ,MGW 9C, MGW 9H ,MGW12C, MGW 12H ,MGW15C ,MGW 15H

HIWIN/OEM brand name name high quanlity linear guide rail for cnc laser chopping equipment linear guidebook parts

Packaging & ShippingPP bag for every single linear shaft, Common exported carton exterior for little get transport by international convey, such as DHL, TNT, UPS

Wooden box outside for massive quantity or really prolonged linear shaft by sea, by air

HIWIN/OEM manufacturer identify high quanlity linear manual rail for cnc laser reducing device linear manual areas

Company InformationThere are numerous kinds of products we can supply, If you are fascinated in them, remember to simply click the photo and see the information.

Company Data:

Our principle:

Top quality 1st, credibility is the important, the value followed

HIWIN/OEM manufacturer name high quanlity linear manual rail for cnc laser chopping equipment linear information parts

Our Companies

We have expert personnel to operate.

We can approach in accordance to your drawings or your specifications customized-created production.

We have the specialist generation group and QC staffs to handle good quality for each action, higher precision equipments (German Chiron FZ15W ,DMG XIHU (WEST LAKE) DIS. MAX3000 Machining Facilities and so on)

are the simple for manufacture company.

If you have any specifications, or any questions, You should kindly let me know, Manufacturing facility direct-selling hefty obligation garden mower flail mower with pto shaft I am really glad to support you and reply you ASAP.

the get in touch with phrases:

Certifications

How to Choose the Right Linear Rail for Your Fishing Rod

Compared to rods, linear rail is cheaper and offers a wide variety of applications. It is also corrosion resistant and has the ability to handle both tearing loads and torque forces.

A wide range of applications

Using a linear rail system is a good way to safely move things through a manufacturing process. They are used in a wide range of industries, and are especially helpful in moving items through packaging and production.

They are typically made from hardened materials such as steel, and have load-supporting balls on both sides. This helps them to handle loads from a few grams to thousands of kilograms, and can withstand overhung loads when paired with another rail.

Linear rails are also used in a variety of applications, including food and beverage production. In this industry, they are required to withstand harsh conditions and must adhere to local health and safety standards.

They are commonly used in weighing machines. They also find applications in CNC machines and moving robot arms in factory lines. The high level of rigidity and load capacity make them a good option for moving products with little friction.

Linear rails can be used vertically or horizontally. They are also a good choice for weight guidance when centered below the rail. They can join multiple rails for very long travel lengths, and can be joined to perform a seventh axis.

These rails can handle travel speeds of up to 5 m/s. They are commonly used in industrial applications, and can handle loads from a few grams to thousands. They are also useful for pneumatic and belt-driven systems, and are often used as actuator guide mechanisms.

There are many different types of linear rails. They range in size and length, and have a variety of processing methods. You can also find simple surface bearings, which are characterized by a low coefficient of friction.

For applications requiring precise positioning and precise travel accuracy, linear rail systems are the way to go. They provide the highest level of rigidity and are capable of achieving travel speeds of up to 5 m/s.

They provide large travel spaces

Various applications may call for the use of a linear rail. These can be square, rectangular or round in shape and can handle loads from a few grams to thousands of kilograms. They also have a long lifespan.

In a nutshell, a linear rail provides low friction guidance for a load. They are used in the industrial sector in a number of applications. Aside from the obvious one’s, a single linear rail can save valuable floor space. It also ostensibly has the trifecta of a runner, power screw and ball bearings.

Linear rails are not for the faint of heart. Aside from the obvious cost, you will also be expected to mount, support and install them properly. You should also consider the size, shape and quality of the components. They can be bought in any length, from a few inches to several feet. They are also made from a wide variety of materials. Some of the materials used include steel, aluminum, and polymers. They can be shaped and joined to achieve very long travel lengths. They are also susceptible to damage.

The name of the game is to choose a good set of quality linear guides. There are two types in common usage today. The first is a runner with ball bearings, and the second is a runner with rollers. The latter is the less expensive choice. Aside from the usual suspects, you can also choose a saddle or fixed slide. It’s a good idea to use them in pairs. They are also the best suited for heavy duty applications.

The most important factor to consider when selecting a linear rail is the load capacity. While a single linear rail can be used in many applications, multiple rails are the best option for the job.

They withstand both tearing loads and torque forces

Generally constructed from corrosion resistant steel, linear rails are sturdy and robust enough to handle a wide variety of applications. They are usually used on mechanical systems with high precision requirements. They also provide a smooth and accurate motion.

In order to achieve the highest level of efficiency, the rail must be accurately supported and installed. It may also require some form of lubrication. The design of the rail may be influenced by factors like size, shape, and frequency of use.

For instance, linear rails are often used for actuator guides. These guide mechanisms provide a smooth, reliable, and low-friction motion. A runner is inserted inside the rail and moves from front to back. The runner may have ball bearings or a pair of sleeve bearings.

Another notable feature of the linear rail is the ability to withstand torque and tearing forces. They are also capable of handling larger loads, providing greater stability to the entire system. The most important feature is the fact that they are easy to install and remove. They are also capable of achieving high speeds.

There are many types of linear rails to choose from. Some may be suitable for consumer applications, while others are more suited for industrial applications. Some of the common factors that affect the lifespan of a rail include size, frequency of use, and mounting. A single rail is a space saver, while dual rails maximize bearing life.

Some of the major components in a linear slide include the runner, the bearings, and the carriage. In addition to the runner, the slide may also feature the motor, power screw, or other components. Some of these features are the smallest relative to the overall linear slide.

They’re cheaper than rods

Choosing the best linear rails for your fishing rod is no small feat. You must understand the characteristics of various rails before you can find the one that best fits your needs. You may also want to consider choosing a rail that will last for many years. This is especially true if you are fishing in saltwater.

The best linear rails are designed with a variety of factors in mind. They will help you achieve precision and longevity. In addition, these guides are made of materials that are durable. They are also affordable. There are a variety of choices, including round and square rails.

The best rods have a good selection of features, including a good reel seat and flexible nickel/titanium snake guides. You should also look for a rod that has a smooth but firm handle and a rod that is easy to use. The best rods will also be a bit pricier, but you will not regret your investment.

The best rods use quality cork and stacks of smaller cork rings. The best rods have a cork handle that has a good feel. This handle has a big flare at the bottom and has narrow cork rings on the top. This handle is the best fly rod handle that you will find.

The best rods also have a well made reel seat that will hold firmly and easily. It should also have thin nylon spacers between the rings for a positive lock up. The reel seat should also be made from an anodized black aluminum up-lock seat with a synthetic gray insert.

The best rods also have reputable guide sets. This includes a new CERECOIL stripping guide made of nickel Titanium. This guide uses a multi-taper design that removes material from the weakest areas, thus improving dampening and recovery.

They’re corrosion-resistant

Stainless steel linear rails are essential in many industries, including vacuum applications, the pharmaceutical industry, and electronic circuit machines. They are also necessary for washing down cycles.

Stainless steel rails have excellent corrosion resistance. The steel surface is coated with an inert layer that prevents the rusting of the steel. Steel surfaces can rust over time, though, and rust can contaminate equipment. It’s important to check with your manufacturer about any corrosion resistance treatments that may be available.

Carbon steel linear bearings can be treated with hard chrome, black chrome, or a corrosion-resistant coating. These bearings are more expensive than those made of austenitic steel, but they provide similar corrosion resistance. They also have a lower hardness.

Silicon Nitride balls are another option. These balls are 40% lighter than steel, so they can carry higher loads without causing electrolysis. They’re also inert to chemicals and are capable of higher speeds. They’re available in closed or open designs. They come in four different sizes. They’re also coated with CZPT coating, which reduces the surface area of the balls in contact with the steel.

Another option is electroless nickel plating, which is inexpensive. This type of plating uses nickel instead of copper to prevent corrosion. It also offers a low friction coefficient.

Another option is drylin(r) linear technology, which combines the corrosion-resistance of thermoplastic bearing liners with shafting. This technology is ideal for chemical washdown environments, as well as those in saltwater environments. These systems also provide excellent rigidity and high load-bearing capacities.

Other types of linear guides are also available. Plain bearing guides may be appropriate for less expensive applications, while round shaft systems may be better for more expensive applications.

editor by czh 2023-03-18