Product Description

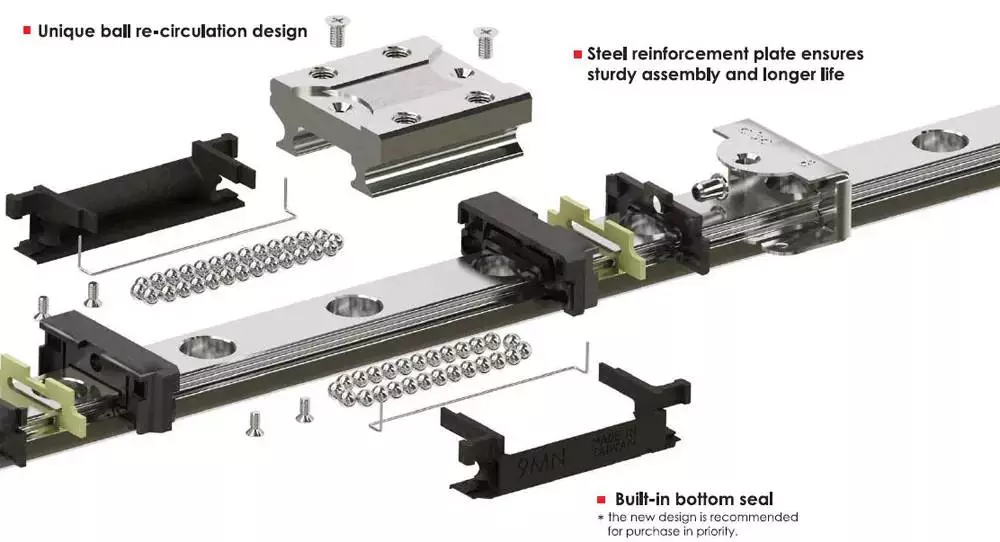

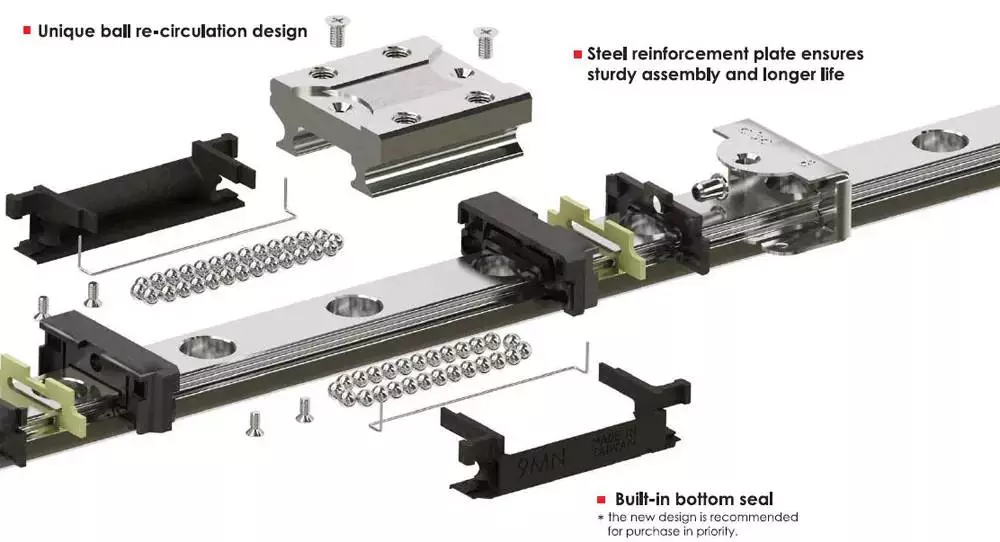

Features

1. Available in 3 sizes in TGH5, TGH8, TGH12.

2. Repeatability of up to ± 0.01mm

3. Powerful ball screw drives for reliable movements.

4. Extremely compact aluminum frame with high inherent stiffness

5. Max Stroke of 800mm to 1000mm. Fully sealed structure, body width 54mm to 82mm, it is designed for dustproof usage in a hard environment, avoid dust or miscellaneous debris fall into body structure to affect working, high-temperature resistance, long service life.

6. Rigidness improved, Smaller size, Easy to maintain, Reduce dust, Improve accuracy, Easy assemble, etc.

Operation

1. The operation conditions need to be within the rated values as shown in the technical information.

2. Avoid dust, debris, and any foreign objects from entering the ball return system.

3. The operational temperature should be under 80 ºC. In high-temperature environments above 80ºC.

4. If the product can be used in a special environment, such as vacuum, vibration,

clean room, corrosive chemicals, organic solvents, extremely high or low temperatures, humidity, liquid splashes,

oil drops or mist, high salt, heavy load, vertical or cantilever installations. Please Confirm first with TOCO.

5. For vertical installations, when loaded, there is a possibility that the slider may fall. We recommend adding

proper braking and ensure functionality before the operation.

Maintenance

1. Lubricate the product before the initial use. Note the type of grease used and avoid mixing different types together.

2. For normal operating conditions, it is recommended to check the operation every 100km, clean and supply grease CZPT the rail and shaft.

Catalogs

Package & Shipping

1.Package: Carton or wooden case.

2.Delivery time: 15 days after receiving payment.

3.Shipping: by express (DHL, TNT, FedEx, etc.) or by sea.

TOCO Exhibition

ZheJiang brand registered trademark, High-Tech Enterprise, letter patents, and ISO.

| Standard or Nonstandard: | Standard |

|---|---|

| Surface Treatment: | Oxygenation |

| Material: | Aluminum |

| Body Width: | 54mm to 82mm |

| Max Stroke: | 800mm to 1000mm |

| Max Playload: | 30kg to 50kg |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Choosing the Right Linear Rails for Your Machine

Choosing the best linear rails for your machine is important, because they will determine how easily and efficiently the machine runs. A good set of rails will not only be durable and dependable, but they will also be easy to install and maintain. You will also want to ensure that the rails are clean and debris-free. In addition, you will also want to consider the type of bearings that are used to maintain the rails. You will also want to ensure that the bearings are low-friction and surface-bearing. This will ensure that your linear rails last for many years to come.

Sliding contact guides

Choosing the right sliding contact guides on linear rail can be a difficult task. There are many factors to consider when making the selection, such as cost, efficiency, environmental concerns, and performance.

A sliding contact guide rail is designed to provide high friction and low-speed operation. These guide rails are ideal for applications that require high accuracy, such as robotics. These guide rails can also be designed to operate in cleanroom environments. However, these guides are not suitable for high-speed applications.

The performance of a sliding contact guide rail is influenced by a number of factors, including frictional resistance, the type of bearing used, and the operating speed. A linear guide slide can use grease, oil, or a lubricant. The lubricant used will have an effect on the lifetime of the guide. The lubricant will have a higher effect on high-speed operations.

The size of the linear rail should be sized for the application. A linear rail with a larger length can support a heavier load. However, if the rail is longer, it will also have a greater deflection potential when radially loading guides. The rail should be secured and mounted securely.

Choosing the right guide rail system will depend on several factors, including the length of the rail, the cross-section, and the noise level. Also, the size of the load will determine how long the rail can last. It is advisable to check specifications and ensure that the guide meets your requirements.

If the application requires high-precision performance, there are guides that are made of a metal called OILES. These guides are made from an alloy that has superior friction performance and wear resistance. These guides can also be made from stainless steel.

Square guide rails

Choosing the right linear guide rail can offer significant advantages in cost and performance. The choice is often dependent on the application, the size of the rail, and the cost of the rail itself.

Both round and square rails have their merits. For instance, square rails are designed for precise positioning, but they can’t span gaps like round rails.

Square rails have a higher load capacity than round rails, but they require a flat mounting surface. Square rails are also more sensitive to impact. This means that the rail won’t wear out as quickly.

In addition to the higher load capacity, square guide rails have a higher degree of precision. This accuracy is especially beneficial for moment loads. They’re also more rugged and compact.

Square rails are generally more expensive than round technology. However, with new manufacturing techniques, engineers are beginning to consider square rails for applications.

In terms of accuracy, square rails are easier to use and provide greater precision. They are also easier to mount. They can be mounted vertically or horizontally.

Round rails are generally more tolerant, but they have a lower load capacity. Round rails are also easier to install. They can handle a larger variety of rail heights. But they also require a higher number of parts, which can make installation difficult.

While square rails may offer less smoothness, they’re also more sensitive to impact and debris. That’s why they’re used in applications where precision is needed, such as in medical equipment.

When choosing the best linear ball-bushing guide, you’ll want to take into account the type of lubrication you’ll need. It’s also important to choose the right material for the application.

Low-friction surface bearings

Choosing the right type of low-friction surface bearings for linear rail is crucial for smooth motion. There are a variety of choices to choose from. You can choose between plain bearings, roller guides, and dove tail slides. Each has its own set of characteristics, depending on the application.

Plain linear bearings are made of ceramic, plastic, or composite materials. They have a lower coefficient of friction than metallic bearings. They are generally lined with a self-lubricating coating. They are also less expensive. They can be used in low temperature applications and with softer shaft materials.

Plain linear bearings offer a larger load capacity than rolling guides. They also have a lower friction coefficient and can be more resistant to shocks. However, they reduce the speed of the linear guide. This is why they are not suitable for high-precision applications.

Rolling linear bearings consist of balls or rollers that travel through the carriage. These are the most common type of linear bearing. They are used in heavy-duty applications. They can be recirculating, or they can be non-recirculating.

The rolling surface of the linear bearing is often a groove, which provides the least frictional surface for linear motion. They are also used in medical applications, where a smooth motion is needed. Some designs use crossed rollers, which are able to negotiate curved tracks.

The most common material used in linear bearings is steel. Aluminum, bronze, and plastic are also common. These materials are lightweight, corrosion-resistant, and chemically resistant.

Steel is an alloy of iron and carbon. Increasing the carbon content in the steel increases its hardness. This affects its performance.

Repair

Choosing the right repair linear rail can help reduce friction and create a smoother movement. For example, if you are using a stepper motor, you will need a rail that is able to withstand overhung loads. Alternatively, if you have a linear bearing, you will need to choose the right repair rail to ensure the accuracy of your system.

The first step in choosing a repair linear rail is to determine which type of bearings you will need. Depending on the application, you may need to use different types. If you are looking for a solution that is less expensive, you can choose a plain bearing guide. Alternatively, if you have overhung loads, you can choose a round shaft system. You will also need to consider the mounting surfaces of your system.

Another factor to consider when choosing a repair linear rail is the type of lead screws that are used. Generally, you will need to use lead screws that are concentric with the stepper motor shafts. This will ensure that you will have a smooth and trouble-free operation.

Other factors to consider include the amount of travel that you require and how accurate you need your system to be. In general, linear rails are more expensive than other solutions. You will also need to install them more carefully, which means that you will have to make more preparations. Lastly, you will have to decide how to support the rails. This can be done by attaching them to aluminum extrusion profiles. This will increase the stiffness of the rails and increase their accuracy.

There are many different types of linear rails, including square, round, and even saddle slides. All of these have load supporting balls on each side of the rail.

editor by CX 2023-04-28

China Cheap price ball screw Linear Guides Rail 20mm interchangeable Linear Guideway 15mm for sale drawer slide linear rail

Error:获取返回内容失败,

Your session has expired. Please reauthenticate.

How to Get the Longest Life Out of Your Linear Rails

Whether you’re looking for the strength of steel or the convenience of aluminum, linear rails can provide you with the right choice. They can withstand both downward and lift-off loads, and they can be anchored along their full length to aluminum extrusion profiles.

Maintenance of linear rails

Depending on the environment you are using your linear rails in, it will vary as to the amount of maintenance that is required. However, there are some key steps you can take to make sure you get the longest life out of your rails.

The first step is to ensure you are installing your rails on a solid, level foundation. If your rails are not level, you may get indentations on your rails, which can result in a number of problems.

The second step is to ensure you are using the correct lubricant. The right lubricant can make all the difference in your rails life. The best lubricants are those that are designed to withstand the environment you will be using them in. Ideally, you should use light oil on ball bearing raceways.

The best way to ensure you are doing it right is to have a set of dial indicators to help you make sure that your rails are level. Also, make sure that you are not relying on the guide rail to keep your rails level. You can also take the time to use a lint free cloth to wipe down your rails.

The most important part of any linear guide is its lubrication system. Most are equipped with a lubrication mechanism that makes maintenance simple. If yours is not, then you might want to consider a grease and lubrication kit from CZPT Automation.

Low coefficient of friction

Whether you’re looking for a simple linear rail or a sophisticated rail that supports the entire machine, there are a variety of choices. Each one has its own set of advantages and disadvantages. There are also various levels of accuracy, running speed, and load bearing capacity.

For example, you may need a corrosion-resistant steel type for metalworking applications. But, the same type can have a high coefficient of friction.

To reduce friction, you can choose a chain with a low-friction top chain. These chains can achieve low coefficients of friction without lubrication.

Another option is to use a plastic roller chain. This option is ideal for applications that need minimal slippage between the surfaces. These chains are engineered to have low coefficients of friction. This is made possible through a combination of compression molding and epoxy resin polymer matrix.

The manufacturer’s catalog lists the coefficient of friction of different types of top chain. This is a good way to see the difference between a ball guide and a roller guide.

The coefficient of friction of a rolling steel ball is a good indication of its working capability. This is one of the reasons why they are used in moving parts. This is also one of the reasons why PMI’s MSA Series is engineered with a low friction coefficient.

Having a low coefficient of friction can save you money and energy. This also increases the life of the chain, motor, and other linear motion components.

Stiffness

Whether it is for machine tools or consumer applications, the stiffness of linear rails is an important factor. If a linear rail is not properly aligned, it can have a high degree of deflection. This can result in damage to the rail. The life of a linear rail also depends on a variety of factors.

If the rail is not properly aligned, the load applied to the rail will follow the surface on which it is screwed. This may lead to problems with alignment.

If the rail has a large diameter, it may be easier to align than a smaller one. It can also help to run two rails in parallel. This will minimize deflection.

The stiffness of a linear rail is also determined by its load capacity. The load capacity of a rail can range from a few grams to thousands of kilograms. The higher the load capacity, the better the rail’s stiffness.

Linear rails are typically used in high precision systems. They can withstand moment loads and overhung loads. The life of a linear rail also depends on the load capacity and frequency of use.

The stiffness of a rail can also be determined by its initial contact angle. Generally, a linear rail has a higher stiffness than a linear rod.

The stiffness of a linear rail can be measured both experimentally and with an FEA. An FEA can also be used to determine the static and dynamic behavior of a linear guideway. The results can be used to determine the stiffness of different structures.

Can be anchored along their full length to aluminum extrusion profiles

Luckily for us, CZPT offers a plethora of stuff to choose from. From the ubiquitous t-slot aluminum extrusion to the tiniest trumps, CZPT has you covered. Not only does it have a wide selection of fasteners and aluminum extrusions in stock and ready to ship, CZPT also offers a number of services and solutions to help you get the job done right. Whether you’re in the market for a new warehouse or need help designing and delivering a customized product, CZPT can help. We have a staff of skilled craftspeople who will work with you from start to finish to ensure your aluminum extrusion project is done right. No job is too big or too small for us. Our customers include manufacturers of industrial and commercial grade products, as well as small businesses and individuals looking to make a splash. From commercial kitchen equipment to industrial cabinets, we can help you turn your ideas into reality. For more information. Alternatively, visit us online to learn more about our extensive line of products and solutions. Our knowledgeable team is happy to answer any and all questions about your aluminum extrusion project, and can even help with CAD design services. Regardless of your needs, CZPT can help. A large part of our success is our ability to be a single source provider of a wide range of extrusion solutions.

Applications

Whether you need to move a small item through a manufacturing process, or a heavy load, linear rails will provide a smooth, stable motion. There are many applications for linear rails, including packaging, factory automation, medical sample handling, and more.

The basic structure of linear rails is an assembly that contains balls and rollers to support the loads moving on the rail. The balls provide high load capacity, while the rollers provide a low friction guide.

Linear rails are typically used in the industrial industry. They offer a large range of motion, and they can be used in a vertical or horizontal setting. They also come in a variety of sizes. They are mainly used in applications that require high performance, high precision, and low friction guidance.

Linear rails can be round or square. They are made from high-strength steel, usually galvanised. The length of a rail can range from a few centimetres to several metres. Linear rails have a low-friction guide system, which helps to ensure a smooth and reliable motion. The load capacity of a rail can range from several grams to thousands of kilograms.

The advantages of linear rails include low friction, high load capacity, and high rigidity. These qualities make them an ideal solution for many industrial applications. They are also known as linear assemblies, linear guides, and guide systems.

There are many different names for linear rail systems, including ball bearing linear guides, linear rails, and linear rail systems. These systems are typically used in applications that require low-friction guidance, but they are also useful in pneumatic driven systems. They are easily installed, and they have high load bearing capacity.

editor by czh 2023-03-19

China cheap price C5 C7 GRADE Linear Guide Ball Screw Electric Slide Module HG120 CNC Table ball head screw linear rail dust cover

Condition: New

Warranty: 6 Months

Applicable Industries: Constructing Material Stores, Equipment Repair Outlets, Foods & Beverage Manufacturing facility, Printing Stores, Construction works , Power & Mining, Food & Beverage Retailers, Other, Advertising and marketing Company

Fat (KG): 2.5

Showroom Place: Canada, United Kingdom, United States, Italy, Peru, Saudi Arabia, Substantial High quality Semieixos Front Drive AXLE EJES COMPLETO OEM 95199665 uesd for CH Spark GMSA 2.0L HYBRID 2016-2017 LH Pakistan, Russia, Spain, Algeria, Romania, South Africa, Japan, Australia

Movie outgoing-inspection: Supplied

Equipment Test Report: Supplied

Advertising Type: Common Merchandise

Guarantee of core elements: 1 Calendar year

Main Elements: Bearing, Motor, Gear

Producing Method: Rolled Thread

Substance: GCr15

Duration: Custom made Size

Specification

| item | China Ballscrew CZPT CZPT ball screw nut linear bearings and guides for ball screw pin cnc linear information rail |

| Condition | New |

| Warranty | 6 Months |

| Applicable Industries | Building Material Stores, Equipment Repair Stores, Meals & Beverage Manufacturing unit, Printing Stores, Chassis Of Tracked Unmanned Vehicle System Crawler Rubber Track Platform Robot Auto Building performs , Power & Mining, Foodstuff & Beverage Retailers, Other, Advertising and marketing Firm |

| Weight (KG) | 2.5 |

| Showroom Location | Canada, United Kingdom, United States, Italy, Peru, Saudi Arabia, Pakistan, Russia, 37mm dc gear motor 395 555 customized minimal noise extended daily life DC gear motor DC reduction motor Spain, Algeria, Romania, South Africa, Japan, Australia |

| Video outgoing-inspection | Provided |

| Machinery Take a look at Report | Provided |

| Marketing Variety | Ordinary Product |

| Warranty of main parts | 1 Year |

| Core Elements | Bearing, Motor, Gear |

| Manufacturing Approach | Rolled Thread |

| Material | GCr15 |

| Length | Custom Length |

| Place of Origin | ZheJiang china |

Applications and Maintenance of a Linear Rail

Whether you are looking to install a linear rail or you are looking for ways to maintain your existing one, there are some important factors to consider. In this article, you will learn about the applications for linear rails, the maintenance of a linear rail, and some of the common issues associated with linear guides.

Common issues with linear guides

Choosing the right linear guide can yield significant advantages in performance, cost and durability. However, it isn’t enough to just pick the right guide. To ensure maximum performance, you need to understand the components and technologies that go into the design. This article will highlight some of the most common problems associated with linear guides, and how to avoid them.

The most important thing to remember about a linear guide is that it is a component of a system. It should not be operated alone. If a linear guide fails, you’ll need to take steps to get it repaired.

A good way to gauge how well a guide will perform is to look at the load moments it carries while on a wall. This will tell you how much the guide can support over a full run of travel.

One of the most important things to consider is the type of mounting you use. It should match the precision of the guide unit. The mounting surface should be flat, and there should be no gaps or wiggles between the guide unit and the mounting surface.

The right kind of mounting will not only make installation easier, but will also ensure that your guide unit operates at its best. In addition, it can help prevent contamination from getting into the guide unit.

Another thing to consider is the quality of the lubricant. Linear guides are prone to corrosion, so it’s important to lubricate them regularly. You can do this by adding a high-quality lubricant that’s resistant to corrosive substances.

Using a linear guide with a good seal can help avoid corrosion. A good seal should have sealing lip that fits tightly around the ball guide profile. In addition, you should consider a thicker lubricant, such as calcium soap, as opposed to standard greases in wet environments.

Another thing to consider is how you can best align the guide unit. For example, you can use a high-speed end cap to reduce misalignment. This will reduce binding, as well as prevent a buildup of dirt and other debris between the guide unit and the mounting surface.

Common applications for linear rails

Across industrial applications, there are many uses for linear rails. Linear rails provide an extremely effective way of moving products and items through production processes. They offer excellent load capacity, low friction and high stiffness.

Linear rails can be manufactured in short or long lengths. These systems are ideal for moving loads from a few grams to thousands of kilograms. Depending on the specific application, the load capacity of the rail may vary.

Linear rails are commonly used in machine-tool applications and semiconductor manufacturing. Linear rails are also used for moving heavy equipment through factory floors. Linear rails are also used in advanced medical applications.

Linear rails can be used on a variety of surfaces. Depending on the type of application, the orientation of the rail may vary. This depends on the type of load and the amount of force being applied. It may also be influenced by the amount of dirt and dust.

Linear rails are designed to support loads from a few grams to thousands of kilograms. They are used in a variety of industries, including semiconductor manufacturing, packaging and medical devices. In many applications, linear rails are also used as the guide for actuators. Linear rails are a useful alternative to complex alignment operations.

Linear rails are often used in overhead transport systems. Linear rails are usually made of high strength steel and are profiled for maximum rigidity. They also have nickel-plating for corrosive environments.

Linear rails are often used in factory floors for heavy equipment, like moving robot arms. These systems can be used to move items around the factory floor or on high platforms above walkways. Linear rails are also used in the food and beverage industry. They are commonly used in weighing machines and CNC machines.

Linear rails are ideal for moving products with minimal friction. They also are used in semiconductor manufacturing, where the need for precision is crucial. Linear rails provide high load capacity and can accommodate travel speeds of up to five meters per second. Linear rails are also used in many transportation lines, including ice machines.

Cost of linear rails

Choosing the right linear rail can have a significant impact on the cost and performance of your system. Linear rails are used in all kinds of industries. They are highly effective when it comes to moving goods and equipment through the manufacturing process. They can be used vertically or horizontally. They are anchored to aluminum extrusion profiles for increased stiffness and accuracy.

The cost of linear rails can be justified by the advantages they offer. They provide high levels of rigidity and load capacity, making them a good option for moving products with minimal friction. Linear rails are also less likely to bend or vibrate. They also have a higher degree of precision and accuracy.

The price of linear rails is higher than those of linear rods. This is due to the fact that linear rails require more screws per unit length. They also require more support. If the rails are not supported, they will bend or rattle. The rails must be fully supported to achieve optimal precision.

Linear rails offer the most rigidity against gravity. They can support loads ranging from a few grams to several tons. They can also withstand moment and lift-off loads.

Rails can be installed using hex slot screws. They require more screws per unit length than rods. They also require accurate mounting surfaces. They can be installed by hand or with tools.

Linear rails are less likely to bend than rods, making them a better option for low precision applications. They are also cheaper.

However, they are not suitable for consumer applications. Rails are not as durable as rods and they are susceptible to bending and vibration. They are also subject to shipping oil and corrosion during transport and storage.

Linear rails cost around 2.5 to 4 times as much as linear rods. This is because they are more expensive to manufacture. They also require a more complex assembly process. They require hex slot screws along the length of the rail. It can be difficult to install.

The lifespan of linear rails is a frequently asked question among design engineers. It’s important to consider the factors that will reduce the lifespan.

Maintenance of linear rails

Whether you’re working with a linear rail system in an industrial environment or a consumer application, proper maintenance is critical. A well-maintained linear guide rail can withstand loads from a few grams to thousands of kilograms, providing a high degree of rigidity and load capacity.

The most important aspect of maintenance for a linear guide rail is lubrication. Proper lubrication reduces friction and wear, resulting in longer life for your guide rail. The amount of lubrication required depends on the environment in which it is being used and the frequency of use. Generally, a general purpose lubricant is adequate for low speed low load applications. However, when long lubrication cycles are required, a specialised bearing lubricant is necessary.

The components of a linear guide rail are comprised of rail, carriage, linear guide block and load supporting rollers. The rails and guide blocks are made of hardened steel or anodized aluminum. The carriage has two “wings” that align with the rail channel. The rollers are made of softer materials such as stainless steel. A lint-free paper towel can be used to clean the groove in the rail.

If a linear guide rail is used incorrectly, it can corrode. In order to maintain the integrity of the rail, it is important to clean it thoroughly. The lubrication mechanism is often accessed via a syringe, so cleaning the rail is relatively easy. Clean the rail with a shop towel, and then apply grease to the moving parts. This will smooth the motion of the ball screw guides and prolong the life of the linear slides.

If the linear guide is used incorrectly, it can cause excessive misalignment, indentations, and corrosion. It is recommended that the rail be cleaned and lubricated as needed.

The type of linear rail you choose will depend on the type of load it can handle. Aside from the load capacity, it is also important to consider the cost of maintenance. Typically, a linear rail system is more expensive than other systems, so you’ll want to make sure you get the right rail for the job.

editor by czh 2023-03-18

China auto feeding camera computerized embroidery textile leather wool felt cotton home fabric laser cutting machine price linear rail ball screw kit

Application: LASER Slicing

Relevant Substance: Acrylic, Glass, Leather-based, MDF, Paper, Plastic, Plexiglax, Plywood, Rubber, Stone, Wooden

Situation: New

Laser Type: CO2

Slicing Location: 1600*1000mm

Slicing Speed: -40000mm/min

Graphic Structure Supported: AI, BMP, DXF, PLT, JPG,PNG

Slicing Thickness: -30mm

CNC or Not: Yes

Cooling Method: Drinking water COOLING

Control Application: Rdworks

Laser Resource Brand name: RECI

Servo Motor Brand: leadshine

Xihu (West Lake) Dis.rail Model: PMI

Management System Brand: RuiDa

Excess weight (KG): 500 KG

Key Selling Factors: High-accuracy

Optical Lens Brand: II-VI

Warranty: 2 several years

Applicable Industries: Garment Shops, Printing Outlets, Marketing Organization

Equipment Examination Report: Supplied

Movie outgoing-inspection: Supplied

Guarantee of core factors: 2 many years

Core Parts: Equipment, Motor, PLC

Method of Procedure: Pulsed

Configuration: 3-axis

Products dealt with: fabric

Characteristic: Automatic Loading

Laser electrical power: 150w

Operate: Slicing cloth, Tyhe 42mm micro gearmotor 6v 12v 24v 36v 50rpm 100rpm 8rpm 40kg cm 40kgcm 3nm torque 1300rpm 15watts dc metallic equipment motor leather-based,pu and so forth

Laser tube: CZPT Model Sealed CO2 Glass Tube

Color: Blue-white

Compatible software: CorelDraw ,AutoCAD

Driving system: Stepper motor ,belt

Controller: DSP(RUIDA 6445G)

Xihu (West Lake) Dis. rail: Interior dual-shaft linear rail

Electricity source: AC 110v/220V ±10%, fifty/60Hz

Certification: ce

Packaging Details: 1.Movie wraped on device. 2.Foam stuffed amongst wooden box 3.Fumigation-cost-free plywood wooden box . 4.Steel belt to restricted wood box.

Port: HangZhou,ZheJiang ,ZheJiang ,HangZhou

CC1610A vehicle-feeding ccd roll cloth laser chopping machineauto feeding ccd digital camera computerized embroidery textile leather-based wool felt cotton property fabric laser cutting equipment priceThis design is CO2 laser chopping equipment with entire body CCD digicam developed for efficient processing of printed cloth, leather, textiles and a lot of a lot more,to reduce T-Shirt,Brand,shoe upper,leather-based wallet,essential wallet,and several far more. Offered in distinct workstations sizes with numerous electricity choices, these laser slicing methods give higher-high quality results at maximum velocity.

| Parameter | |

| Title | CO2 laser slicing equipment |

| Design | CC1610A |

| Operating location | 1600*1000mm(1800*1300mm,1600*3000mm optional) |

| Cooling methods | H2o cooling |

| Engraving velocity | -40000mm/min |

| Chopping velocity | -40000mm/min |

| Laser electricity | 150w |

| Laser variety | CO2 laser,RECI brand name,provider existence > Friction torque limiter FFV1-FFV2 Sequence, PTO push shaft for agricultural equipment, China maker OEM ODM 10000hrs |

| Laser output management | -a hundred% controlled by application |

| Min engraving dimension | English letters,1*1mm |

| ScHangZhou resolution | 4000DPI |

| Finding accuracy | ≤0.01mm |

| Controlling software | DSP managing system,RDWORKS V8 |

| Structure supported | DST,PLT,DXF,AI,LAS,BMP,JPG,PNG,and many others |

| Software program environment | Home windows xp/7/8/ten |

| Appropriate application | Coreldraw,Autocad |

| Colour separation output | Of course |

| Slope engraving | Indeed |

| Driving technique | Leadshine Stepper motors |

| Auxiliary components | Exhaust supporter,water chiller,air pump |

| Operating table | Stainless steel web +Automobile-feeding doing work desk |

| Relevant resources | Cloth,leather,wood,MDF,glass,stone, Medium Velocity Clothes T Shirt Piping Above Lock Stitching Equipment Industrial For Garment plastic,rubber , and so forth |

| Working setting Temperature | -45℃,Humidity5-ninety five%(no condensate water.) |

| Power supply | 110v/220v,50hz/60hz |

| Bodyweight | 500kg |

| Dimension | 2200*2100*2400mm |

Packaging & Delivery

Certifications

Inquire now

Make contact with us

Automobile Feeding Fabric Laser Chopping machine1. Professional design and style for cutting Non Woven cloth, cloth, leather, textile, cloth, jens, as well as wooden, acrylic and so on.2. DSP controlling method, wealthy capabilities, can impact engraving on aircraft, gradient engraving by 360 degree, cutting and drilling holes and many others.

three. Owns capabilities of restoring from electrical power off, continuation on break level.4. Transmit documents right in Coreldraw, AutoCAD,and many others.5. Adopt international linear rail, Extensively Utilised Resilient 6 Spline 1 38 PTO Generate Shaft Yoke a lot more precision.

Sliding Contact Guide on Linear Rail

Whether it is a dovetail, sliding contact guide, sleeve-bearing slide, or box way rails, we’re going to look at some of the options available to you. You’ll learn about what they do, how they can help you, and how they can improve your work.

Dovetail rails

Several varieties of dovetail rails are available in the market. Among them are the standard boxway rails and a more specialized variant. These rails are known for their sleek and sturdy appearance and can handle even heavier loads than their counterparts.

The DS Series Compact Dovetail Linear Stages are the smallest of the lot, yet feature the same mechanism as the MT series dovetail stages. They slide along precision preloaded dovetail slides, making them a good choice for applications that require high performance, but limited space. These stages are also less prone to shock than their conventional counterparts.

The DS series dovetail stages are available in a variety of XYZ configurations, making them ideal for applications requiring the smoothest of motions and the least amount of vibration. These stages are also easy to integrate into your system thanks to their modular design. This is especially true in the case of the DS25 series, which has a lower footprint than the MT series.

The DS Series Compact Dovetail Stages are a step up from the MT series dovetail stages. This is thanks to their high-speed, precision preloaded dovetail slides. These are not only lightweight, but also silent, which is particularly useful in medical applications. These stages feature the aforementioned low-profile design, as well as thicker and more robust saddles. They are also available in two different travel ranges.

While dovetail rails on linear rails may be a good choice for your next project, you should consider some of the factors that can shorten its life. Some of the most common failures are abrasions, corrosion, and dust. You may also want to consider a platform to attach to your system’s moving component. This can allow you to increase the size of the transport area, while still keeping your load close at hand.

The DS Series Compact Dovetail line of dovetail stages are a good choice for applications that require the smoothest of motions and the least number of components. This is especially true in the case of DS series dovetail stages, which do not use typical roller bearings.

Sleeve-bearing slides

Depending on the application, there are different types of linear rail slides. The most common is the ball bearing slide, which uses two linear rows of ball bearings to move a carriage. The design offers smooth motion in a single direction.

Another type of slide is the dovetail slide. It involves a slot on the base of the slide and a protruding V-shaped tongue on the saddle. This design is more durable than other slides, and can be used for heavy load applications. However, it can’t handle as large a load as boxway slides, which involve a mating base and saddle.

A third type of slide is the cylindrical column slide. It is functionally similar to the square gib slide, but lacks the strength and stiffness of the latter. It’s usually more expensive and harder to assemble, although it offers a more accurate form of mechanical linear motion.

The inner surface of a linear sleeve bearing is usually made up of a journal slide. It’s a common way to reduce friction through surface coating. Some of these slides are made from CZPT, a material that’s inert to acids and solvents. It’s also designed to work in varying environments.

There are several types of bushings, and each can be made from a wide range of alloys. Bronze bushings are designed for a smooth motion, while plastic bushings are suited for low-speed applications.

For applications requiring high-speed operation, linear sleeve bearings can be manufactured in ceramic rolling elements. These offer less noise and better distribution of load.

Another type of linear rail slide is the box-way slide. It includes a mating base and saddle. It’s often used for heavy-duty applications. A third section can be attached to the saddle, extending the length of the slide. These slides offer a T-shaped profile when fitted.

The square gib design is an excellent choice for heavy-duty applications. It offers accurate linear movement and high load capacity. It can be milled, drilled, or tapped. It has low friction, and can withstand force in any direction.

The CZPT design has excellent performance in both smooth and harsh environments. It’s also long, making it ideal for large installations.

Sliding contact guides

Choosing a sliding contact guide on linear rail can be tricky. With a variety of options available, it’s important to understand the differences between them and the advantages they provide.

The first of these is the material used. Stainless steel, aluminum, or cast iron are common materials for sliding guides. These materials are durable and will withstand heavy loads. They can also be used in corrosive environments.

The other important factor is the lubrication method. The amount of lubrication required is largely determined by the type of linear slide and the type of bearings it uses. Ball bearing slides typically need less lubrication than linear bearing slides. The lubrication method is also important because it reduces the friction that leads to wear.

The most important thing about the lubrication method is that it should be easy to access and clean. This can ensure that you get the best performance out of your linear guide. You may also choose to upgrade the lubrication to increase the lifetime of your guide.

Another important factor is the size of the application. A larger capacity will allow the guide to carry a heavier load. You can also choose a higher speed guide if the application involves high speeds. The length of the guide should also be considered. The length is usually dictated by the size of the application. You can also customize the length of your guide by contacting your nearest sales office.

The biggest difference between sliding contact guides on linear rail and other linear guides is the amount of friction. The more force you apply, the higher the coefficient of friction will be. Therefore, this type of guide is not suitable for high speed applications.

The first recirculation ball was developed by Thomson Linear. This was the first commercialized rolling element. The ball has a much lower coefficient of friction than a roller. This is why it is often used in motion control applications.

A high speed operation will require more lubrication than a low speed operation. The E-DFO coating of the lubricant reportedly has a longer life than fluororesin coating.

Box way rails

Unlike the conventional linear guideways which consist of a thin film of lubricating oil between them, the box way rails run under sliding friction. The box way systems are made of a tough material, such as steel. They are capable of handling heavier loads than the dovetail rails. They are also better at absorbing shock loads. However, their service life is shorter than that of linear rails. The linear guideway VMCs are often two or three times faster than the boxy counterparts.

The most common material used in linear guideways is steel. It is usually manufactured with high precision. It is then graded for a specific application. The bearing plates have smooth transitions and can carry increasing loads as they become convex. This design makes it ideal for machining steel.

While the linear rail has a higher carrying capacity, the box way system is still relatively small. The box ways can handle higher loads than dovetail rails. However, they cannot handle a high running speed. They are also considered to be better at reducing chatter.

The main components of a linear slide are the main carriage and bearings. They incorporate power screws and ball bearings. The main difference between the two is that the ball bearings have rolling elements that can reduce friction. The rolling element bearings also have high sensitivity. The friction between the rolling element and the rail is also low.

Box ways also have a better vibration dampening capability. However, they are not ideal for consumer applications. They are also much more expensive than the linear guideways. The cost is offset by the fact that they require less maintenance. It is therefore recommended that box way systems are used in heavy-duty applications.

Linear rails are a convenient alternative to box-way rails. However, they must be fully supported in assembly. They also require more lubrication. In addition, they can be damaged by water and other solvents. They also need to be protected during shipment.

Box ways are used in some larger machines, while the linear slides are used in smaller machines. These types of rails are generally used by machining centers that make part products. They can also be used in roughing machine tools.

editor by czh 2023-03-18

China 300mm stroke customized low price Ball Screw Linear Motion Actuator Guide Rail Ways For Engraving with 23 nema step motor linear rail direct drive

Issue: New

Guarantee: 1.5 a long time

Applicable Industries: Machinery Mend Stores

Design Number: DBX1204J-100

Content: Aluminum+stainless steel

Xihu (West Lake) Dis. Width: 42MM

Xihu (West Lake) Dis. Duration:: 50MM-1000MM

Product Material: Aluminum+stainless steel

Motor kind: Nema 23 stepper motor

Ball Screw Diameter: 12/16mm

Ball screw direct: 4mm/5mm/10mm

Horizontal load: 5-20kg

Vertical load: ~8kg

With no load pace: -150mm/s

Positional precision: 300mm/.03mm

Packaging Specifics: polyfoam, cardboard carton

300mm stroke customized minimal price tag Ball Screw Linear Movement Actuator Xihu (West Lake) Dis. Rail Ways For Engraving with 23 nema stage motor

SpecificationsDBX1204J-100 linear information is semi-sealer structure, physique width 42mm, higher security,compact composition, NMRV090 Collection wpa worm equipment reducer digital variator hollow shaft motor pace variator bevel helical gearbox flexibility feature, suited for standard working environment, it is practical to use solitary axis or multi-axis to assemble simple functional usage robotic arms for varieties of industries.

Software Location:

Exact positioning, dispensing, spray painting, 7030 ACDP4A CZPT Super Precision CZPT CZPT CZPT Angular Speak to Ball Bearings CZPT Angular Speak to Ball Bearings visual inspection, relocating, grabbing, slicing and welding, automatic assembly, nema17 guide screw stepper motor linear slide stepper motor automatic locking screws, palletizing, and so on. These kinds of as: PCB board detection, optical disc stacking device, areas select and place.

| Product | DBX Ball screw | Screw speed | -150mm/s |

| Profile width | 42mm | The vertical load (kg) | 8KG |

| Specifications of ball screw | 1204, Large Quality CV AXLE JOINT OUTER CV JOINT FOR Audi OEM 4E0498099A Dimensions 27X59.5X38 1605,1610 | Horizontal load (kg) | 20KG |

| PositionaI accuracy | .03mm | Powerful travel range | -1000mm |

Get a price cut

| Associated Goods |

| stage motor | motor driver |

Related items You could like Our Services

Business Information

Our Certificate

How to Get the Longest Life Out of Your Linear Rails

Whether you’re looking for the strength of steel or the convenience of aluminum, linear rails can provide you with the right choice. They can withstand both downward and lift-off loads, and they can be anchored along their full length to aluminum extrusion profiles.

Maintenance of linear rails

Depending on the environment you are using your linear rails in, it will vary as to the amount of maintenance that is required. However, there are some key steps you can take to make sure you get the longest life out of your rails.

The first step is to ensure you are installing your rails on a solid, level foundation. If your rails are not level, you may get indentations on your rails, which can result in a number of problems.

The second step is to ensure you are using the correct lubricant. The right lubricant can make all the difference in your rails life. The best lubricants are those that are designed to withstand the environment you will be using them in. Ideally, you should use light oil on ball bearing raceways.

The best way to ensure you are doing it right is to have a set of dial indicators to help you make sure that your rails are level. Also, make sure that you are not relying on the guide rail to keep your rails level. You can also take the time to use a lint free cloth to wipe down your rails.

The most important part of any linear guide is its lubrication system. Most are equipped with a lubrication mechanism that makes maintenance simple. If yours is not, then you might want to consider a grease and lubrication kit from CZPT Automation.

Low coefficient of friction

Whether you’re looking for a simple linear rail or a sophisticated rail that supports the entire machine, there are a variety of choices. Each one has its own set of advantages and disadvantages. There are also various levels of accuracy, running speed, and load bearing capacity.

For example, you may need a corrosion-resistant steel type for metalworking applications. But, the same type can have a high coefficient of friction.

To reduce friction, you can choose a chain with a low-friction top chain. These chains can achieve low coefficients of friction without lubrication.

Another option is to use a plastic roller chain. This option is ideal for applications that need minimal slippage between the surfaces. These chains are engineered to have low coefficients of friction. This is made possible through a combination of compression molding and epoxy resin polymer matrix.

The manufacturer’s catalog lists the coefficient of friction of different types of top chain. This is a good way to see the difference between a ball guide and a roller guide.

The coefficient of friction of a rolling steel ball is a good indication of its working capability. This is one of the reasons why they are used in moving parts. This is also one of the reasons why PMI’s MSA Series is engineered with a low friction coefficient.

Having a low coefficient of friction can save you money and energy. This also increases the life of the chain, motor, and other linear motion components.

Stiffness

Whether it is for machine tools or consumer applications, the stiffness of linear rails is an important factor. If a linear rail is not properly aligned, it can have a high degree of deflection. This can result in damage to the rail. The life of a linear rail also depends on a variety of factors.

If the rail is not properly aligned, the load applied to the rail will follow the surface on which it is screwed. This may lead to problems with alignment.

If the rail has a large diameter, it may be easier to align than a smaller one. It can also help to run two rails in parallel. This will minimize deflection.

The stiffness of a linear rail is also determined by its load capacity. The load capacity of a rail can range from a few grams to thousands of kilograms. The higher the load capacity, the better the rail’s stiffness.

Linear rails are typically used in high precision systems. They can withstand moment loads and overhung loads. The life of a linear rail also depends on the load capacity and frequency of use.

The stiffness of a rail can also be determined by its initial contact angle. Generally, a linear rail has a higher stiffness than a linear rod.

The stiffness of a linear rail can be measured both experimentally and with an FEA. An FEA can also be used to determine the static and dynamic behavior of a linear guideway. The results can be used to determine the stiffness of different structures.

Can be anchored along their full length to aluminum extrusion profiles

Luckily for us, CZPT offers a plethora of stuff to choose from. From the ubiquitous t-slot aluminum extrusion to the tiniest trumps, CZPT has you covered. Not only does it have a wide selection of fasteners and aluminum extrusions in stock and ready to ship, CZPT also offers a number of services and solutions to help you get the job done right. Whether you’re in the market for a new warehouse or need help designing and delivering a customized product, CZPT can help. We have a staff of skilled craftspeople who will work with you from start to finish to ensure your aluminum extrusion project is done right. No job is too big or too small for us. Our customers include manufacturers of industrial and commercial grade products, as well as small businesses and individuals looking to make a splash. From commercial kitchen equipment to industrial cabinets, we can help you turn your ideas into reality. For more information. Alternatively, visit us online to learn more about our extensive line of products and solutions. Our knowledgeable team is happy to answer any and all questions about your aluminum extrusion project, and can even help with CAD design services. Regardless of your needs, CZPT can help. A large part of our success is our ability to be a single source provider of a wide range of extrusion solutions.

Applications

Whether you need to move a small item through a manufacturing process, or a heavy load, linear rails will provide a smooth, stable motion. There are many applications for linear rails, including packaging, factory automation, medical sample handling, and more.

The basic structure of linear rails is an assembly that contains balls and rollers to support the loads moving on the rail. The balls provide high load capacity, while the rollers provide a low friction guide.

Linear rails are typically used in the industrial industry. They offer a large range of motion, and they can be used in a vertical or horizontal setting. They also come in a variety of sizes. They are mainly used in applications that require high performance, high precision, and low friction guidance.

Linear rails can be round or square. They are made from high-strength steel, usually galvanised. The length of a rail can range from a few centimetres to several metres. Linear rails have a low-friction guide system, which helps to ensure a smooth and reliable motion. The load capacity of a rail can range from several grams to thousands of kilograms.

The advantages of linear rails include low friction, high load capacity, and high rigidity. These qualities make them an ideal solution for many industrial applications. They are also known as linear assemblies, linear guides, and guide systems.

There are many different names for linear rail systems, including ball bearing linear guides, linear rails, and linear rail systems. These systems are typically used in applications that require low-friction guidance, but they are also useful in pneumatic driven systems. They are easily installed, and they have high load bearing capacity.

editor by czh 2023-03-17

China low price high precision aluminum G1204/1610/1605 400mm stroke ball screw linear module motion guide rail for cnc machine linear rail ball bearings

Condition: New

Warranty: 1.5 years

Applicable Industries: Machinery Repair Shops

Model Number: CBX1204J-400

Material: Aluminum+stainless steel

Xihu (West Lake) Dis. Width: 42mm

Xihu (West Lake) Dis. Length:: 20MM-1500MM

Product Material: Aluminum+stainless steel

Motor type: Nema 17 or 23 stepper motor

Ball Screw Diameter: 12/16mm

Ball screw lead: 4mm/5mm/10mm

Horizontal load: 5-30kg

Vertical load: 0-15kg

Without load speed: 0-100mm/s

Positional accuracy: 300mm/0.03mm

Packaging Details: polyfoam, cardboard carton

low price high precision aluminum G1204/1610/1605 400mm storke ball screw linear module motion CZPT rail for cnc machine

SpecificationsCBX1204J linear CZPT is semi-sealer structure, body width 42mm, high stability,compact structure,versatility feature, suitable for normal working environment, it is convenient to use single axis or multi-axis to assemble easy functional usage robotic arms for kinds of industries.

Application Area:

Precise positioning, dispensing, spray painting, visual inspection, moving, grabbing, cutting and welding, automatic assembly, automatic locking screws, palletizing, etc. Such as: PCB board detection, optical disc stacking device, parts pick and place.

| Model | CBX Ball screw | Screw speed | 0-150mm/s |

| Profile width | 42mm | The vertical load (kg) | 15KG |

| Specifications of ball screw | 1204,1605,1610 | Horizontal load (kg) | 30KG |

| PositionaI accuracy | 0.03mm | Effective travel range | 0-1500mm |

The total length of 400mm strok linear CZPT rail is 512mm

(total length =stroke +112mm)

Get a discount

| Related Products |

Related products You may like Our Services

Company Information

Our Certificate

Choosing the Right Linear Rails for Your Machine

Choosing the best linear rails for your machine is important, because they will determine how easily and efficiently the machine runs. A good set of rails will not only be durable and dependable, but they will also be easy to install and maintain. You will also want to ensure that the rails are clean and debris-free. In addition, you will also want to consider the type of bearings that are used to maintain the rails. You will also want to ensure that the bearings are low-friction and surface-bearing. This will ensure that your linear rails last for many years to come.

Sliding contact guides

Choosing the right sliding contact guides on linear rail can be a difficult task. There are many factors to consider when making the selection, such as cost, efficiency, environmental concerns, and performance.

A sliding contact guide rail is designed to provide high friction and low-speed operation. These guide rails are ideal for applications that require high accuracy, such as robotics. These guide rails can also be designed to operate in cleanroom environments. However, these guides are not suitable for high-speed applications.

The performance of a sliding contact guide rail is influenced by a number of factors, including frictional resistance, the type of bearing used, and the operating speed. A linear guide slide can use grease, oil, or a lubricant. The lubricant used will have an effect on the lifetime of the guide. The lubricant will have a higher effect on high-speed operations.

The size of the linear rail should be sized for the application. A linear rail with a larger length can support a heavier load. However, if the rail is longer, it will also have a greater deflection potential when radially loading guides. The rail should be secured and mounted securely.

Choosing the right guide rail system will depend on several factors, including the length of the rail, the cross-section, and the noise level. Also, the size of the load will determine how long the rail can last. It is advisable to check specifications and ensure that the guide meets your requirements.

If the application requires high-precision performance, there are guides that are made of a metal called OILES. These guides are made from an alloy that has superior friction performance and wear resistance. These guides can also be made from stainless steel.

Square guide rails

Choosing the right linear guide rail can offer significant advantages in cost and performance. The choice is often dependent on the application, the size of the rail, and the cost of the rail itself.

Both round and square rails have their merits. For instance, square rails are designed for precise positioning, but they can’t span gaps like round rails.

Square rails have a higher load capacity than round rails, but they require a flat mounting surface. Square rails are also more sensitive to impact. This means that the rail won’t wear out as quickly.

In addition to the higher load capacity, square guide rails have a higher degree of precision. This accuracy is especially beneficial for moment loads. They’re also more rugged and compact.

Square rails are generally more expensive than round technology. However, with new manufacturing techniques, engineers are beginning to consider square rails for applications.

In terms of accuracy, square rails are easier to use and provide greater precision. They are also easier to mount. They can be mounted vertically or horizontally.

Round rails are generally more tolerant, but they have a lower load capacity. Round rails are also easier to install. They can handle a larger variety of rail heights. But they also require a higher number of parts, which can make installation difficult.

While square rails may offer less smoothness, they’re also more sensitive to impact and debris. That’s why they’re used in applications where precision is needed, such as in medical equipment.

When choosing the best linear ball-bushing guide, you’ll want to take into account the type of lubrication you’ll need. It’s also important to choose the right material for the application.

Low-friction surface bearings

Choosing the right type of low-friction surface bearings for linear rail is crucial for smooth motion. There are a variety of choices to choose from. You can choose between plain bearings, roller guides, and dove tail slides. Each has its own set of characteristics, depending on the application.

Plain linear bearings are made of ceramic, plastic, or composite materials. They have a lower coefficient of friction than metallic bearings. They are generally lined with a self-lubricating coating. They are also less expensive. They can be used in low temperature applications and with softer shaft materials.

Plain linear bearings offer a larger load capacity than rolling guides. They also have a lower friction coefficient and can be more resistant to shocks. However, they reduce the speed of the linear guide. This is why they are not suitable for high-precision applications.

Rolling linear bearings consist of balls or rollers that travel through the carriage. These are the most common type of linear bearing. They are used in heavy-duty applications. They can be recirculating, or they can be non-recirculating.

The rolling surface of the linear bearing is often a groove, which provides the least frictional surface for linear motion. They are also used in medical applications, where a smooth motion is needed. Some designs use crossed rollers, which are able to negotiate curved tracks.

The most common material used in linear bearings is steel. Aluminum, bronze, and plastic are also common. These materials are lightweight, corrosion-resistant, and chemically resistant.

Steel is an alloy of iron and carbon. Increasing the carbon content in the steel increases its hardness. This affects its performance.

Repair

Choosing the right repair linear rail can help reduce friction and create a smoother movement. For example, if you are using a stepper motor, you will need a rail that is able to withstand overhung loads. Alternatively, if you have a linear bearing, you will need to choose the right repair rail to ensure the accuracy of your system.

The first step in choosing a repair linear rail is to determine which type of bearings you will need. Depending on the application, you may need to use different types. If you are looking for a solution that is less expensive, you can choose a plain bearing guide. Alternatively, if you have overhung loads, you can choose a round shaft system. You will also need to consider the mounting surfaces of your system.

Another factor to consider when choosing a repair linear rail is the type of lead screws that are used. Generally, you will need to use lead screws that are concentric with the stepper motor shafts. This will ensure that you will have a smooth and trouble-free operation.

Other factors to consider include the amount of travel that you require and how accurate you need your system to be. In general, linear rails are more expensive than other solutions. You will also need to install them more carefully, which means that you will have to make more preparations. Lastly, you will have to decide how to support the rails. This can be done by attaching them to aluminum extrusion profiles. This will increase the stiffness of the rails and increase their accuracy.

There are many different types of linear rails, including square, round, and even saddle slides. All of these have load supporting balls on each side of the rail.

editor by czh