Product Description

ZCF BRIEF INTRODUCTION:

ZCF PRECISION TECHNOLOGY(HangZhou) CO.,LTD. IS A PROFESSIONAL MANUFACTURER OFLINEARXIHU (WEST LAKE) DIS.,LINEAR MODULE AND BALL SCREW ETC.SHE IS LOCATED IN HangZhou CITY,ZheJiang ,CHINA.THE NEW FACTORY COVERS 33333 SQUARE METERS AND HOLDS A BUILDING AREA OF 16000 SQUARE METERS AT PRESENT. WITH OVER 10 YEARS’ EFFORT OF OUR WHOLE TEAM. AND ALSO TRUST AND SUPPORT FROM OUR RESPECTED CUSTOMERS. WE ARE SO LUCKY TO BECOME ONE STRONG BRAND IN CHINA, WHO MAKE INTERNATIONAL STHangZhouRD PRODUCTS.WE AIM SERVE CUSTOMERS WORLDWIDELY.

PRODUCTS PHOTOS:

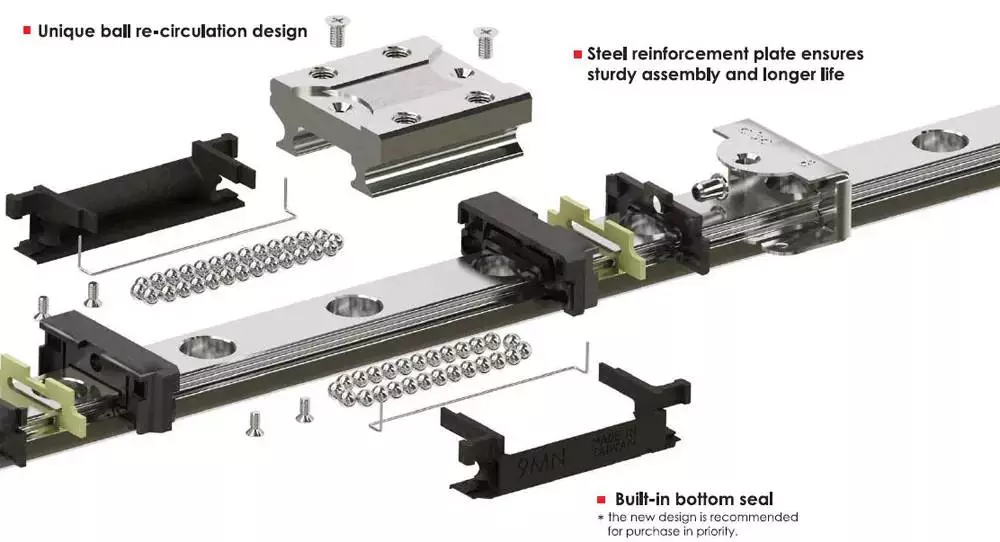

CH SERIES BODY STRUCTURE:

1.ROLLING CYCLE SYSTEM: SLIDER, XIHU (WEST LAKE) DIS. RAIL, END COVER, STEEL BALL, BALL HOLDER;

2.LUBRICATION SYSTEM: OIL NOZZLE AND TUBING JOINT

3.DUST-PROOF SYSTEM: OIL SCRAPER, NEGATIVE DUST SEAL DUST-PROOF SHEET, XIHU (WEST LAKE) DIS. RAIL BOLT COVER, METAL SCRAPER

ACCURACY LEVEL

1. THE ACCURACY OF CH SERIES LINEAR XIHU (WEST LAKE) DIS.S CAN BE DIVIDED INTO FIVE LEVELS: COMMON, HIGH, PRECISION, SUPER-PRECISION AND ULTRA-PRECISION. CUSTOMERS CAN CHOOSE THE ACCURACY LEVEL ACCORDING TO THE ACCURACY REQUIREMENT OF EQUIPMENT.

2. ACCURACY OF NON-INTERCHANGEABLE LINEAR XIHU (WEST LAKE) DIS.:

| MODEL | CH – 15, 20 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF N | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

3. MOTION ACCURACY CHART

| RAIL LENGTH (mm) | ACCURACY LEVEL (µm) | |||||

| C | H | P | SP | UP | ||

| ~ | 100 | 12 | 7 | 3 | 2 | 2 |

| 100 ~ | 200 | 14 | 9 | 4 | 2 | 2 |

| 200 ~ | 300 | 15 | 10 | 5 | 3 | 2 |

| 300 ~ | 500 | 17 | 12 | 6 | 3 | 2 |

| 500 ~ | 700 | 20 | 13 | 7 | 4 | 2 |

| 700 ~ | 900 | 22 | 15 | 8 | 5 | 3 |

| 900 ~ | 1,100 | 24 | 16 | 9 | 6 | 3 |

| 1,100 ~ | 1,500 | 26 | 18 | 11 | 7 | 4 |

| 1,500 ~ | 1,900 | 28 | 20 | 13 | 8 | 4 |

| 1,900 ~ | 2,500 | 31 | 22 | 15 | 10 | 5 |

| 2,500 ~ | 3,100 | 33 | 25 | 18 | 11 | 6 |

| 3,100 ~ | 3,600 | 36 | 27 | 20 | 14 | 7 |

| 3,600 ~ 4,000 | 37 | 28 | 21 | 15 | 7 | |

SELECTION CRITERIA

1. PRODUCT APPLICATIONS:

1). CH SERIES: GRINDING MACHINE, MILLING MACHINE, LATHE, DRILLING MACHINE, INTEGRATED PROCESSING MACHINE, EDM MACHINE, BORING MACHINE, WIRE CUTTING MACHINE, PRECISION

2). CE SERIES: INDUSTRIAL AUTOMATION MACHINERY, SEMICONDUCTOR MACHINERY, LASER ENGRAVING MACHINE, PACKAGING MACHINE;

3). CGN/CGW SERIES: PRINTER, MACHINE ARM, ELECTRONIC INSTRUMENT AND SEMICONDUCTOR EQUIPMENT.

2. SELECTION OF ACCURACY LEVEL:

C, H, P, SP, UP LEVELS DEPEND ON EQUIPMENT ACCURACY REQUIREMENTS.

3. SELECTION OF SIZE:

1). ACCORDING TO EXPERIENCE;

2). LOAD STATUS;

3). IF LINEAR XIHU (WEST LAKE) DIS.WAY IS USED IN CONJUNCTION WITH BALL SCREW, SELECT SIMILAR SIZE AS EXTERNAL DIAMETER OF THE SCREW. IF THE EXTERNAL DIAMETER OF THE SCREW IS 35 MM, SELECT CH35.

4. CALCULATING THE MAXIMUM LOAD OF SLIDER:

1). CALCULATING THE MAXIMUM EQUIVALENT LOAD OF A SINGLE SLIDER WITH REFERENCE TO THE LOAD CALCULATION TABLE

2). CONFIRMATION THAT THE STATIC SAFETY FACTOR OF THE SELECTED STRAIGHT-LINE XIHU (WEST LAKE) DIS. SHOULD EXCEED THE VALUE LISTED IN THE TABLE OF STATIC SAFETY FACTOR

LUBRICATION:

IF THE LINEAR XIHU (WEST LAKE) DIS. IS NOT PROPERLY LUBRICATED, THE FRICTION OF ROLLING PARTS WILL INCREASE, AND LONG-TERM USE WILL BECOME THE MAIN REASON FOR SHORTENING THE LIFE. LUBRICANTS PROVIDE THE FOLLOWING FUNCTIONS:

(1). REDUCE FRICTION OF ROLLING PARTS, PREVENT BURNS AND REDUCE WEAR;

(2). FORMING OIL FILM BETWEEN ROLLING SURFACE AND ROLLING SURFACE CAN PROLONG ROLLING FATIGUE LIFE;

(3). PREVENTING RUST.

1. GREASE LUBRICATION:

EACH GROUP OF LINEAR XIHU (WEST LAKE) DIS.WAYS CAN BE SEALED WITH LITHIUM SOAP-BASED GREASE TO LUBRICATE THE BEAD GROOVE TRACK BEFORE LEAVING THE FACTORY. ALTHOUGH THE GREASE IS NOT EASY TO LOSE, IN ORDER TO AVOID INSUFFICIENT LUBRICATION CAUSED BY LUBRICATION LOSS, IT IS SUGGESTED THAT CUSTOMERS SHOULD SUPPLEMENT THE GREASE ONCE MORE WHEN THE DISTANCE REACHES 100 KM. AT THIS TIME, GREASE CAN BE INJECTED INTO THE SLIDER BY MEANS OF THE OIL NOZZLE ATTACHED TO THE SLIDER. LUBRICATING GREASE IS SUITABLE FOR SITUATIONS WHERE THE SPEED IS NOT MORE THAN 60 M/MIN AND THE COOLING EFFECT IS NOT REQUIRED.

T : OIL INJECTION FREQUENCY (hour); Ve : SPEED (m/min)

2. OIL (OIL) LUBRICATION:

IT IS RECOMMENDED THAT CUSTOMERS USE LUBRICATING OIL WITH A CONSISTENCY OF ABOUT 32-150 CZPT TO LUBRICATE LINEAR XIHU (WEST LAKE) DIS.S. CZPT CAN INSTALL THE TUBING JOINT AT THE ORIGINAL POSITION OF THE OIL DISCHARGE NOZZLE ACCORDING TO THE CUSTOMER’S NEEDS, SO THE CUSTOMER ONLY NEEDS TO CONNECT THE PRESET TUBING OF THE MACHINE TO THE TUBING JOINT. THE LOSS OF LUBRICATING OIL IS FASTER THAN THAT OF LUBRICATING GREASE. WHEN USING, ATTENTION MUST BE PAID TO THE ADEQUACY OF OIL SUPPLY. IF INSUFFICIENT LUBRICATION EASILY CAUSES ABNORMAL WEAR OF LINEAR XIHU (WEST LAKE) DIS.S AND REDUCES THEIR SERVICE LIFE, IT IS SUGGESTED THAT THE FREQUENCY OF LUBRICATING OIL SHOULD BE ABOUT 0.3CM3/HR. CUSTOMERS CAN USE IT ACCORDING TO THEIR USE CONDITIONS. LUBRICATING OIL IS SUITABLE FOR VARIOUS LOADS AND SPEEDS, BUT IT IS NOT SUITABLE FOR HIGH TEMPERATURE LUBRICATION BECAUSE OF ITS VOLATILITY.

DUST-PROOF DEVICE(OPTIONS)

1. DUST-PROOF DEVICE CODE:

IF YOU NEED THE FOLLOWING DUST-PROOF EQUIPMENT, PLEASE ADD THE CODE AFTER THE PRODUCT MODEL.

INSTALLATION OF LINEAR XIHU (WEST LAKE) DIS.WAY

THE INSTALLATION METHOD OF LINEAR XIHU (WEST LAKE) DIS. MUST BE SET ACCORDING TO THE OPERATING CONDITION OF THE MACHINE, SUCH AS THE DEGREE OF VIBRATION AND IMPACT FORCE, THE REQUIRED WALKING ACCURACY AND THE LIMITATION OF THE MACHINE.WHEN PAIRING NON-INTERCHANGEABLE LINEAR XIHU (WEST LAKE) DIS.S, ATTENTION SHOULD BE PAID TO THE DIFFERENCE BETWEEN THE REFERENCE RAIL AND THE DRIVEN RAIL. THE ACCURACY OF THE DATUM LEVEL ON THE SIDE OF THE DATUM RAIL IS HIGHER THAN THAT OF THE DRIVEN RAIL, SO IT CAN BE USED AS THE SUPPORTING SURFACE FOR THE BED INSTALLATION. THE REFERENCE RAIL IS MARKED WITH MA, AS SHOWN IN THE FIGURE.

1. FIXING METHODS

WHEN THE BED IS SUBJECTED TO VIBRATION AND IMPACT FORCE, THE XIHU (WEST LAKE) DIS. RAIL AND SLIDER MAY DEVIATE FROM THE ORIGINAL FIXED POSITION AND AFFECT THE ACCURACY. IN ORDER TO AVOID SIMILAR SITUATION, IT IS SUGGESTED TO USE THE FOUR FIXED WAYS LISTED BELOW TO FIX THE XIHU (WEST LAKE) DIS. RAIL AND SLIDER TO ENSURE THE ACCURACY OF THE MACHINE.

2. INSTALLATION OF LINEAR RAIL:

|

US $14-19 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Machines |

|---|---|

| Material: | Steel |

| Structure: | Machine Table |

| Installation: | All |

| Driven Type: | Slide |

| Carrying Capacity: | Weight Level |

###

| Samples: |

US$ 20/Meter

1 Meter(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| MODEL | CH – 15, 20 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF N | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

###

| RAIL LENGTH (mm) | ACCURACY LEVEL (µm) | |||||

| C | H | P | SP | UP | ||

| ~ | 100 | 12 | 7 | 3 | 2 | 2 |

| 100 ~ | 200 | 14 | 9 | 4 | 2 | 2 |

| 200 ~ | 300 | 15 | 10 | 5 | 3 | 2 |

| 300 ~ | 500 | 17 | 12 | 6 | 3 | 2 |

| 500 ~ | 700 | 20 | 13 | 7 | 4 | 2 |

| 700 ~ | 900 | 22 | 15 | 8 | 5 | 3 |

| 900 ~ | 1,100 | 24 | 16 | 9 | 6 | 3 |

| 1,100 ~ | 1,500 | 26 | 18 | 11 | 7 | 4 |

| 1,500 ~ | 1,900 | 28 | 20 | 13 | 8 | 4 |

| 1,900 ~ | 2,500 | 31 | 22 | 15 | 10 | 5 |

| 2,500 ~ | 3,100 | 33 | 25 | 18 | 11 | 6 |

| 3,100 ~ | 3,600 | 36 | 27 | 20 | 14 | 7 |

| 3,600 ~ 4,000 | 37 | 28 | 21 | 15 | 7 | |

|

US $14-19 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Machines |

|---|---|

| Material: | Steel |

| Structure: | Machine Table |

| Installation: | All |

| Driven Type: | Slide |

| Carrying Capacity: | Weight Level |

###

| Samples: |

US$ 20/Meter

1 Meter(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| MODEL | CH – 15, 20 unit : mm | ||||

| ACCURACY LEVEL | COMMON | HIGH | PRECISION | HIGH-PRECISION | ULTRA-PRECISION |

| (C) | (H) | (P) | (SP) | (UP) | |

| TOLERANCE OF H | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF N | ± 0.1 | ± 0.03 | 0- 0.03 | 0- 0.015 | 0- 0.008 |

| TOLERANCE OF MUTUAL H | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| TOLERANCE OF MUTUAL N | 0.02 | 0.01 | 0.006 | 0.004 | 0.003 |

| MOTION PARALLELISM OF C ON A | MOTION ACURACY | ||||

| MOTION PARALLELISM OF D ON B | MOTION ACURACY | ||||

###

| RAIL LENGTH (mm) | ACCURACY LEVEL (µm) | |||||

| C | H | P | SP | UP | ||

| ~ | 100 | 12 | 7 | 3 | 2 | 2 |

| 100 ~ | 200 | 14 | 9 | 4 | 2 | 2 |

| 200 ~ | 300 | 15 | 10 | 5 | 3 | 2 |

| 300 ~ | 500 | 17 | 12 | 6 | 3 | 2 |

| 500 ~ | 700 | 20 | 13 | 7 | 4 | 2 |

| 700 ~ | 900 | 22 | 15 | 8 | 5 | 3 |

| 900 ~ | 1,100 | 24 | 16 | 9 | 6 | 3 |

| 1,100 ~ | 1,500 | 26 | 18 | 11 | 7 | 4 |

| 1,500 ~ | 1,900 | 28 | 20 | 13 | 8 | 4 |

| 1,900 ~ | 2,500 | 31 | 22 | 15 | 10 | 5 |

| 2,500 ~ | 3,100 | 33 | 25 | 18 | 11 | 6 |

| 3,100 ~ | 3,600 | 36 | 27 | 20 | 14 | 7 |

| 3,600 ~ 4,000 | 37 | 28 | 21 | 15 | 7 | |

The Benefits of Using a Linear Rail in Your Industrial Machine

Generally speaking, linear rail is a material used for transportation. This material can be used in various different ways, including the transportation of goods and machinery. However, there are certain things that you should keep in mind before using it. These include the cost, the accuracy of travel, and the resistance to flexing.

Common uses

Using a linear rail can provide a variety of benefits. They provide low friction guidance, allow for a wide range of motion, and offer reliability. They are also compact and can be used for a variety of applications.

Linear rails are often used in automated assembly lines, conveyor systems, and machine tools. They also work well for pneumatic-driven systems. They can be used for moving loads from small to large in diameter and can handle speeds up to five meters per second. They are typically more expensive than other systems.

Linear rails come in a wide variety of designs. They can be mounted on a variety of surfaces and have different levels of load bearing capacity. They can also be used to connect multiple rails for very long travel lengths.

Linear rails are usually used in applications that require high accuracy. For example, they are often used in machine tools and laser welding machines. They are also used in the production of large objects. They are also used in 3D printing machines. They are also used in medical devices and special vehicles.

Linear rails require careful mounting. They need to be fully supported and have accurate mounting surfaces. They also need to be protected during assembly and shipping. Linear rails are typically made from steel or stainless steel. They are also available in a variety of sizes.

Linear slides are also known as linear motion bearings. They feature bearing contacts, plain surface bearings, recirculating or non-recirculating designs, and race profiles. The sliding contact guide rail is perfect for high accuracy applications.

Linear rails also have the capability to support overhung loads. They can be used alone or in combination with linear guides. They can withstand loads from a few grams to thousands of kilograms.

High level of travel accuracy

Using linear rails in your industrial machine will give you the benefits of a robust, well-supported design. They can handle loads of thousands of kilograms while reducing frictional drag. This is especially true for high-speed, heavy-duty applications.

The best part is that you can choose from a wide variety of options. From standard, multi-point, to end-to-end and even the modular type, there is a linear rail solution for your needs. Whether you want a low-cost solution or a high-end system, CZPT can help you with your industrial needs.

A high level of travel accuracy is a must for any linear stage. There are many factors to consider when choosing the best linear rails for your application. The best way to go about determining the best option is to determine your application’s specific needs and requirements. From there, the experts at CZPT can help you make a well-informed decision. They are experts in all things linear and can recommend the best options for your particular needs.

Aside from high travel accuracy, linear rails offer a multitude of other benefits. For instance, you can minimize the motion of the rails by mounting them in parallel. This will increase the life of the bearings while also reducing the deflection of the system as a whole. You can also choose a rail system that will accommodate overhung loads. This is especially true for linear applications that have high-speed, heavy-duty needs.

The high-tech industry has been abuzz with a number of new and exciting innovations. One such is the integration of an I-beam support with a linear guide system. The I-beam support is ideal for industrial applications, such as robotics.

Resistance to flexing

Besides being a spruced up version of the ancient horseshoe, the linear rail has some impressive properties, including its ability to bend without breaking, and a high degree of self-alignment. It also has the honor of being one of the only types of rails that will withstand a plethora of shocks and jolts, and has some of the lowest lifecycle costs in its class. A large number of rails are actually made from polymer rather than aluminum, but that is another story altogether. The most expensive rails are manufactured from aluminum. The best ones are made from a proprietary polymer, which is said to have the lowest lifecycle costs.

There are two main types of linear rails, the standard type which are fixed at one end, and the more modern and modern variant, which are self-aligned. The latter is actually more important than the former. A good rule of thumb is to consider the more expensive variants first, as they are suited to more rigorous testing and inspection.

Easy to machine

Choosing the right linear rail system depends on the specific needs of the enterprise. It is important to consider how long the rail will last, as well as other factors that can influence its lifespan.

Linear rail systems are designed to support the movement of equipment through production. The system is easy to maintain and is suitable for high-speed applications.

Linear rails are typically supported by aluminum extrusions. They are commonly fixed at each end of the rail. Linear rails can have short lengths or longer dimensions. They are commonly installed with hex slot screws along the length of the rail. Additional linear rail screws can be installed to increase the rigidity of the rail system.

Linear rails have higher load-bearing capacity than hard rails. Hard rails are used in heavy-duty applications, such as machining large molds. Linear rails are suitable for more precision applications, such as small precision molds.

Linear rails have higher accuracy. In addition, they provide a smooth motion. Linear rails also offer less resistance to bending and vibration. However, the use of linear rails requires more support during installation. In addition, the assembly process is tedious.

Linear rails can be used in a wide variety of industries. They are also useful in CNC machining. Most finishing machine tools are manufactured using high-precision linear rails.

Linear rails have higher requirements for processing and transportation. They can also be more expensive to maintain. However, they provide high-speed operation that improves precision. They are also easier to replace than hard track. The process is similar to replacing a screw.

Choosing a rail depends on the enterprise’s production. Some rails have high load-bearing capacity, while others are less expensive. The running speed of the rail system is also a factor.

Cost

Choosing the right rail can give significant advantages in both performance and durability. While there are many types of rails on the market, a good guideline can help you determine which one is best for your application.

The right rail can reduce your application’s total cost of ownership. However, you should be careful not to make the mistake of installing the wrong one. If you install the wrong rail, you can end up with corrosion, excessive misalignment, noise, and reduced life expectancy.

The cost of linear rails will vary depending on the length of the rail, the type of rail, and the material it is made of. However, the most cost-effective rail is one that is made of corrosion resistant steel alloys.

The cost of linear rails is also dependent on the size of the rail. Typically, larger runners are more effective for higher load capacity applications.

Linear rails can also be manufactured in short lengths. However, installing one of these rails is not easy. They have different tools and require a different assembly process.

The cost of linear rails is 2.5 to four times higher than that of rods. While the cost is high, the benefits can be significant. A linear rail provides high rigidity, high accuracy, and higher speed. They are also less likely to bend or deform under heavy load.

The cost of linear rails is often offset by the ability to achieve high speed and precision. However, the cost of installing these rails is not worth it. The same motor can achieve higher speeds using linear rods. However, installing linear rails is a much more difficult process.

The cost of linear rails also depends on the environment where they will be installed. If the rail is placed in a dirty or wet environment, it may lead to reduced precision, corrosion, and damage.

editor by czh 2022-11-26