Product Description

Hairise Plastic Sliding Linear Conveyor Side Xihu (West Lake) Dis. Rail

| Brand Name | Hairise |

| Material | ABS,PMMA,PC,PP,PU,PA,POM,PE,UPE,Teflon,etc. |

| Manufacturing Equipments |

CNC Machining Center, Milling machine,Sawing machine, Machining Center(4 axis), CNC Milling Machine, Turning Machine, CNC Milling&Turning Center, CNC Turning/Lathe Machine, etc |

| Inspection Equipments |

3D Measure Instrument, CMM, Spectrum Analyzers, Electronic balance, Microscope, Altimeter , Calipers, Micrometer,etc. |

| Tolerance | ‘+-0.05mm |

| Drawing Format | PDF/DWG/DXF/IGS/STEP,etc |

| Application field | Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

| Manufacturing process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Rapid Prototyping, Turning, |

| Shape | As per your drawing Or the sample |

| Color service | Customization |

| QC inspection | Make sure 100% inspection before the delivery |

Advantages of the CZPT products:

1.this products are convenient to assembly and maintain

2.All color could be available

3.this modular conveyor belt can bear High mechanical strength

4.this modular conveyor belt has Excellent product handling performance

5.these modular conveyor belts are wear resistance and Oil Resistant

6.we are a professional conveyor system manufacturer, our product line contains modular belt, slat top chain, conveyor spare parts, conveyor system.

7.we can provide good after-sale service.

8.every product can be customized

Application:

Bakery, Dairy, Fruit, and Vegetable

We have extensive experience in developing specialized solutions tailored to the needs of many different Bakery industry segments: bread and bun, fresh pastry (oven and fried pastry), pizza, pasta (fresh and dry), frozen bread, frozen pastry, cookies, and crackers, with our material handling equipment conveyor systems conveyor plastic modular belt conveyor you can get surprised!

Meat Poultry Seafood

With belts and accessories designed to meet the specific needs of fruit and vegetable processing and packaging applications, CZPT is committed to helping customers achieve their operational and business goals.

Hairise continues to develop new and better ways for customers to increase throughput efficiency, improve sanitation, and reduce the costs of belt ownership.

Material handling equipment conveyor systems conveyor plastic modular belt conveyor technology to meet the specific challenges of seafood processors.

Ready Meals

Ready meal customers who equip their lines with CZPT Industrial plastic slat table top food grade conveyor chain realize many critical benefits, including:

·Reduced sanitation costs and improved food safety

·Improved line efficiency and maintain product alignment

·Reduced unscheduled downtime and reduced labor needs

Mu Jia Automation Technology(ZheJiang ) Co, Ltd.

MuJia is an integrated company engaged in the R&D, manufacture and sale of slat top chain,modular belt,conveyor system and other related components almost 20 years. Insisting on the operation principle of “Quality Based and Service First”, our company has won a high reputation through many years of development. We also cooperate with some well-known domestic and overseas enterprises.

Our head office located in ZheJiang ,new factory located in ZheJiang province,covers an areas of 15,000 square meter,there are 3 main buildings:office building,conveyor assembly workshop and production workshop.More than 10 machines for producing,many hundreds of item models for meeting customer variety requirements.Our main products are modular belt,slat top chain,flexible chain,conveyor system,comb,rail,sprocket and other conveyor related components.They are widely used in food, soft drink, packaging & manufacturing, tobacco, medicine & chemical, electronics, automobiles and logistics industries.

Q1. Where is your factory located? How can I visit there?

A: All our clients, from home or abroad, are warmly welcomed to visit us. Before you visit our company, we can connect by phone! Our company is located in ZheJiang , China, near the ZheJiang Xihu (West Lake) Dis.ao International Airport. And our factory is in ZheJiang HangZhou, we will arrange cars to there.

Q2. I don’t know what belt I currently use. Can you help me identify my belt?

A: Our online belt identifier can help you narrow down the series and style of your current belt. If you need more specific information on plastic conveyor chain belt parts manufacturers, contact me freely for plastic chains/ belts/ PU/PVC/Rubber belts/ other components and conveyors.

Q3. What can you do If the products were broken?

(1) If goods were broken once you bought from me,I would replace them freely according to the proven photos.

(2) If the goods were broken when you used, we could provide 5 year quality guarantee for plastic conveyor chain belt parts manufacturers under common working environment.

Q4. Does CZPT provide PDF files of products?

A: Yes, in our download center you can find PDF files for a large number of our products.If you can not find what you are looking for, send me your request by email or contact me on Wechat or Whatsapp freely.

| Type: | Plastic Sliding Linear Conveyor Side Guide Rail |

|---|---|

| Company Type: | Factory, Welcome to Visit |

| Certificate: | ISO, SGS |

| Application: | Conveyor Rail |

| Application Industry: | Food, Drinks, Chemicals, Packaging etc. |

| Delivery Time: | One Week After Receiving Payment |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand Name | Hairise |

| Material | ABS,PMMA,PC,PP,PU,PA,POM,PE,UPE,Teflon,etc. |

| Manufacturing Equipments |

CNC Machining Center, Milling machine,Sawing machine, Machining Center(4 axis), CNC Milling Machine, Turning Machine, CNC Milling&Turning Center, CNC Turning/Lathe Machine, etc |

| Inspection Equipments |

3D Measure Instrument, CMM, Spectrum Analyzers, Electronic balance, Microscope, Altimeter , Calipers, Micrometer,etc. |

| Tolerance | ‘+-0.05mm |

| Drawing Format | PDF/DWG/DXF/IGS/STEP,etc |

| Application field | Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

| Manufacturing process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Rapid Prototyping, Turning, |

| Shape | As per your drawing Or the sample |

| Color service | Customization |

| QC inspection | Make sure 100% inspection before the delivery |

| Type: | Plastic Sliding Linear Conveyor Side Guide Rail |

|---|---|

| Company Type: | Factory, Welcome to Visit |

| Certificate: | ISO, SGS |

| Application: | Conveyor Rail |

| Application Industry: | Food, Drinks, Chemicals, Packaging etc. |

| Delivery Time: | One Week After Receiving Payment |

###

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Brand Name | Hairise |

| Material | ABS,PMMA,PC,PP,PU,PA,POM,PE,UPE,Teflon,etc. |

| Manufacturing Equipments |

CNC Machining Center, Milling machine,Sawing machine, Machining Center(4 axis), CNC Milling Machine, Turning Machine, CNC Milling&Turning Center, CNC Turning/Lathe Machine, etc |

| Inspection Equipments |

3D Measure Instrument, CMM, Spectrum Analyzers, Electronic balance, Microscope, Altimeter , Calipers, Micrometer,etc. |

| Tolerance | ‘+-0.05mm |

| Drawing Format | PDF/DWG/DXF/IGS/STEP,etc |

| Application field | Parts are used on vehicles, printing machines, food processing machines, textile machines, electronic machines, etc. |

| Manufacturing process | CNC machining Broaching, Drilling, Milling, Other Machining Services, Rapid Prototyping, Turning, |

| Shape | As per your drawing Or the sample |

| Color service | Customization |

| QC inspection | Make sure 100% inspection before the delivery |

How to Get the Longest Life Out of Your Linear Rails

Whether you’re looking for the strength of steel or the convenience of aluminum, linear rails can provide you with the right choice. They can withstand both downward and lift-off loads, and they can be anchored along their full length to aluminum extrusion profiles.

Maintenance of linear rails

Depending on the environment you are using your linear rails in, it will vary as to the amount of maintenance that is required. However, there are some key steps you can take to make sure you get the longest life out of your rails.

The first step is to ensure you are installing your rails on a solid, level foundation. If your rails are not level, you may get indentations on your rails, which can result in a number of problems.

The second step is to ensure you are using the correct lubricant. The right lubricant can make all the difference in your rails life. The best lubricants are those that are designed to withstand the environment you will be using them in. Ideally, you should use light oil on ball bearing raceways.

The best way to ensure you are doing it right is to have a set of dial indicators to help you make sure that your rails are level. Also, make sure that you are not relying on the guide rail to keep your rails level. You can also take the time to use a lint free cloth to wipe down your rails.

The most important part of any linear guide is its lubrication system. Most are equipped with a lubrication mechanism that makes maintenance simple. If yours is not, then you might want to consider a grease and lubrication kit from CZPT Automation.

Low coefficient of friction

Whether you’re looking for a simple linear rail or a sophisticated rail that supports the entire machine, there are a variety of choices. Each one has its own set of advantages and disadvantages. There are also various levels of accuracy, running speed, and load bearing capacity.

For example, you may need a corrosion-resistant steel type for metalworking applications. But, the same type can have a high coefficient of friction.

To reduce friction, you can choose a chain with a low-friction top chain. These chains can achieve low coefficients of friction without lubrication.

Another option is to use a plastic roller chain. This option is ideal for applications that need minimal slippage between the surfaces. These chains are engineered to have low coefficients of friction. This is made possible through a combination of compression molding and epoxy resin polymer matrix.

The manufacturer’s catalog lists the coefficient of friction of different types of top chain. This is a good way to see the difference between a ball guide and a roller guide.

The coefficient of friction of a rolling steel ball is a good indication of its working capability. This is one of the reasons why they are used in moving parts. This is also one of the reasons why PMI’s MSA Series is engineered with a low friction coefficient.

Having a low coefficient of friction can save you money and energy. This also increases the life of the chain, motor, and other linear motion components.

Stiffness

Whether it is for machine tools or consumer applications, the stiffness of linear rails is an important factor. If a linear rail is not properly aligned, it can have a high degree of deflection. This can result in damage to the rail. The life of a linear rail also depends on a variety of factors.

If the rail is not properly aligned, the load applied to the rail will follow the surface on which it is screwed. This may lead to problems with alignment.

If the rail has a large diameter, it may be easier to align than a smaller one. It can also help to run two rails in parallel. This will minimize deflection.

The stiffness of a linear rail is also determined by its load capacity. The load capacity of a rail can range from a few grams to thousands of kilograms. The higher the load capacity, the better the rail’s stiffness.

Linear rails are typically used in high precision systems. They can withstand moment loads and overhung loads. The life of a linear rail also depends on the load capacity and frequency of use.

The stiffness of a rail can also be determined by its initial contact angle. Generally, a linear rail has a higher stiffness than a linear rod.

The stiffness of a linear rail can be measured both experimentally and with an FEA. An FEA can also be used to determine the static and dynamic behavior of a linear guideway. The results can be used to determine the stiffness of different structures.

Can be anchored along their full length to aluminum extrusion profiles

Luckily for us, CZPT offers a plethora of stuff to choose from. From the ubiquitous t-slot aluminum extrusion to the tiniest trumps, CZPT has you covered. Not only does it have a wide selection of fasteners and aluminum extrusions in stock and ready to ship, CZPT also offers a number of services and solutions to help you get the job done right. Whether you’re in the market for a new warehouse or need help designing and delivering a customized product, CZPT can help. We have a staff of skilled craftspeople who will work with you from start to finish to ensure your aluminum extrusion project is done right. No job is too big or too small for us. Our customers include manufacturers of industrial and commercial grade products, as well as small businesses and individuals looking to make a splash. From commercial kitchen equipment to industrial cabinets, we can help you turn your ideas into reality. For more information. Alternatively, visit us online to learn more about our extensive line of products and solutions. Our knowledgeable team is happy to answer any and all questions about your aluminum extrusion project, and can even help with CAD design services. Regardless of your needs, CZPT can help. A large part of our success is our ability to be a single source provider of a wide range of extrusion solutions.

Applications

Whether you need to move a small item through a manufacturing process, or a heavy load, linear rails will provide a smooth, stable motion. There are many applications for linear rails, including packaging, factory automation, medical sample handling, and more.

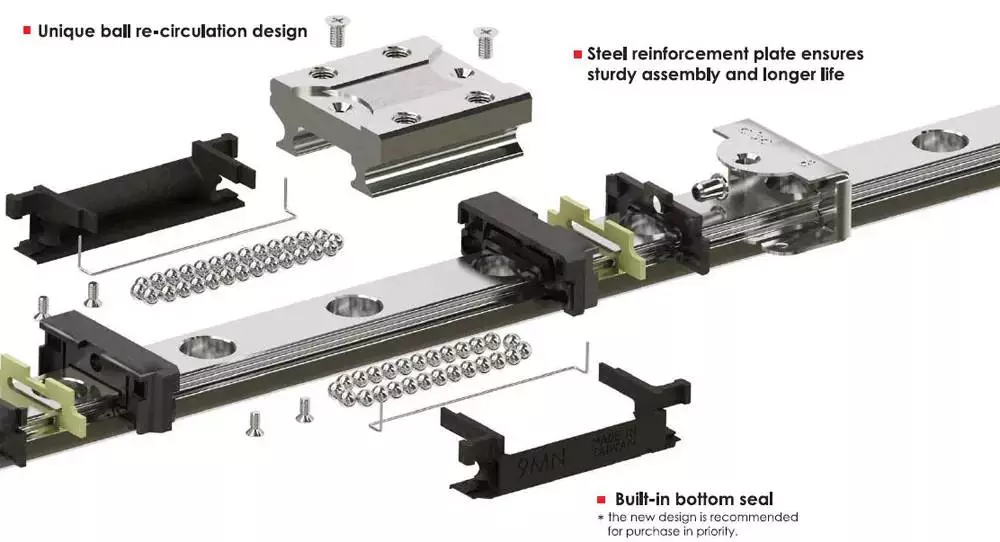

The basic structure of linear rails is an assembly that contains balls and rollers to support the loads moving on the rail. The balls provide high load capacity, while the rollers provide a low friction guide.

Linear rails are typically used in the industrial industry. They offer a large range of motion, and they can be used in a vertical or horizontal setting. They also come in a variety of sizes. They are mainly used in applications that require high performance, high precision, and low friction guidance.

Linear rails can be round or square. They are made from high-strength steel, usually galvanised. The length of a rail can range from a few centimetres to several metres. Linear rails have a low-friction guide system, which helps to ensure a smooth and reliable motion. The load capacity of a rail can range from several grams to thousands of kilograms.

The advantages of linear rails include low friction, high load capacity, and high rigidity. These qualities make them an ideal solution for many industrial applications. They are also known as linear assemblies, linear guides, and guide systems.

There are many different names for linear rail systems, including ball bearing linear guides, linear rails, and linear rail systems. These systems are typically used in applications that require low-friction guidance, but they are also useful in pneumatic driven systems. They are easily installed, and they have high load bearing capacity.

editor by czh 2022-11-28